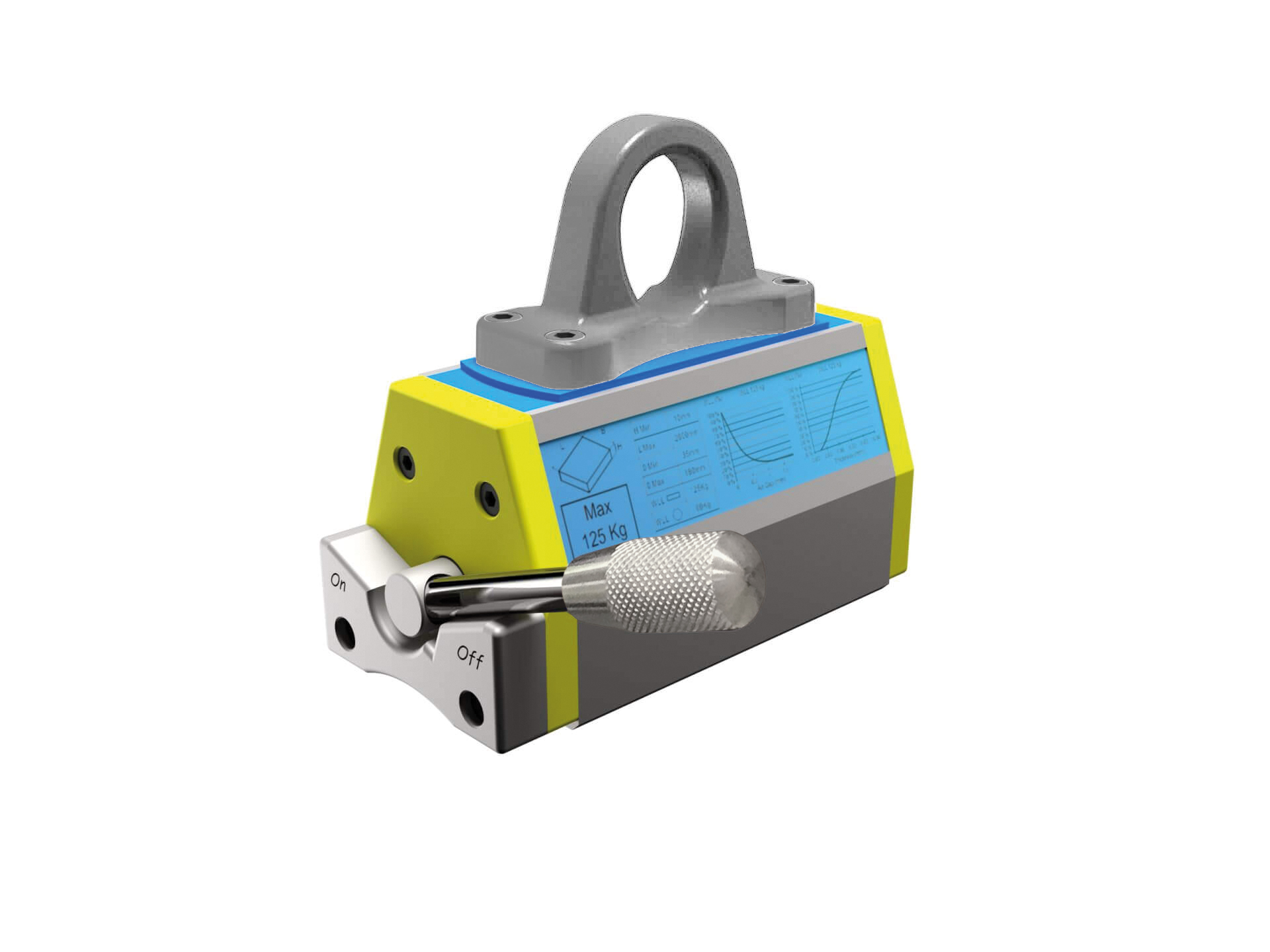

MHM-IT2

Product description

MAGNETIC NEODYMIUM LEVER LIFTERS SUITABLE FOR HANDLING BOTH FLAT AND ROUND FERROUS LOADS

| MODEL | MHM-IT2-125 | MHM-IT2-250 | MHM-IT2-500 | MHM-IT2-1000 | MHM-IT2-2000 |

| MAXIMUM WORKING LOAD ON A FLAT SURFACE | 125 Kg | 250 Kg | 500 Kg | 1000 Kg | 2000 Kg |

| MAXIMUM WORKING LOAD ON A ROUND SURFACE | 60 Kg | 125 Kg | 250 Kg | 500 Kg | 1000 Kg |

ADVANTAGES OVER CONVENTIONAL SYSTEMS:

• Reduced leadtime during both loading and unloading of the work-piece;

• Increased safety: no more risky slinging operations required.

• Easily accessible and better exploitable work-piece surface;

• Increased gripping versatility in case of pieces with different shapes and sizes or with uneven surfaces;

• No deformation and/or damage to the work-piece caused by mechanical clamping.

TECHNICAL FEATURES:

STURDINESS: the dimensions of each component have been correctly calibrated to ensure a high resistance to wear over time. Especially the Mag and Demag lever has been designed to withstand accidental impacts during free positioning of the lifting magnet. The sturdiness and interchangeability of all removable components (from the lifting hook to the containment plates and the cam guide of the lever) guarantee minimum maintenance costs.

SAFETY: the safety coefficient 3:1, required by current legal standards, has been deliberately increased by 10-15% to ensure a high level of reliability over a long period of time.

RELIABILITY: the production process includes thehomogeneous polarisation of the magnets only after the lifting magnet has been fully assembled, in order to create a perfectly balanced magnetic field on the inside. The production cycle is completed by the final testing, performed on each lifting magnet and guaranteed by the attached certificate.

Click here to download the facsimile of the acceptance testing.

ACCESSORIES

• It is possible to mount profilable and interchangeable pole extensions for uneven surfaces and low thicknesses;