Solutions to eliminate the problem of magnetic residual from the workpiece

There can sometimes be uncertainty in the adoption of magnetic solutions for clamping and lifting: this doubt is caused by the possibility that a magnetic charge remains inside the workpiece. This is an eventuality that can in fact occur, although in a much lower way than perceived: the magnetic residue that could remain in the metal piece is not predictable in advance, that is before processing, and can vary randomly.

For this reason, SPD has designed a series of solutions aimed at eliminating the magnetic residues present in metal parts after their processing. Below is an in-depth analysis of the topic and specific information about SPD solutions for demagnetization:

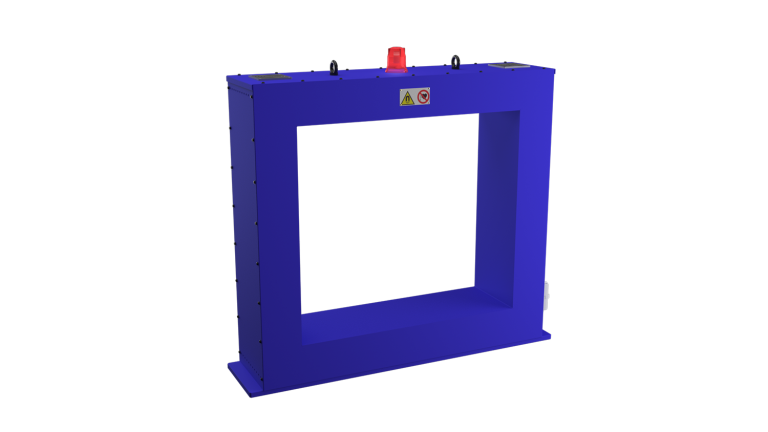

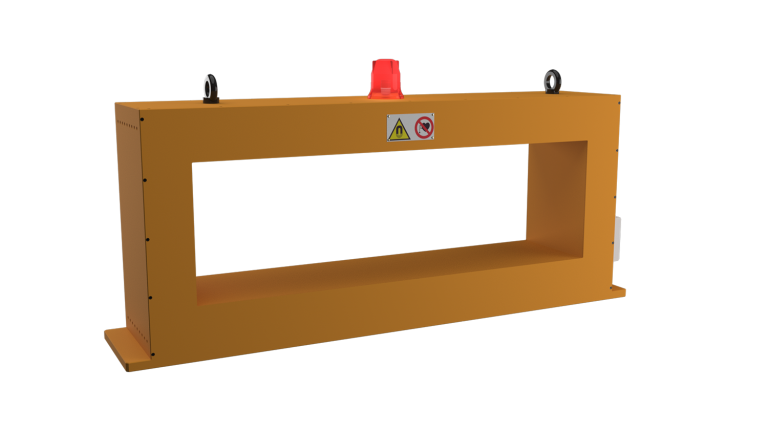

- Bench demagnetizer

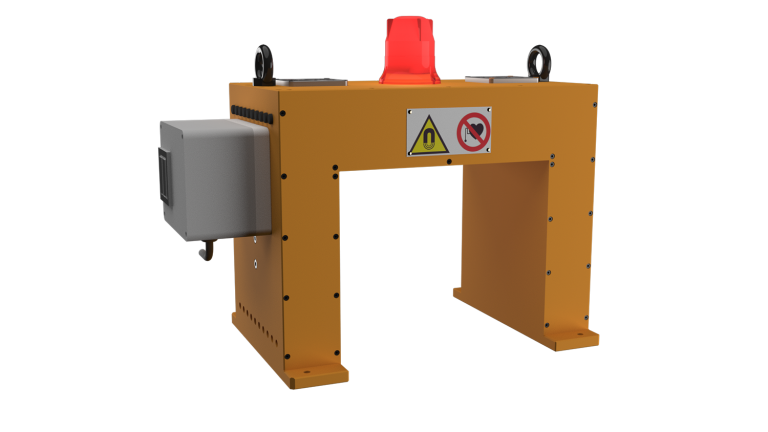

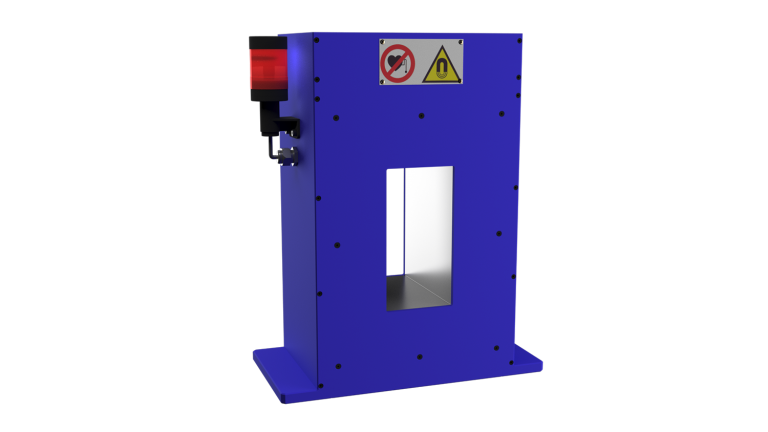

- Enhanced bench demagnetizer

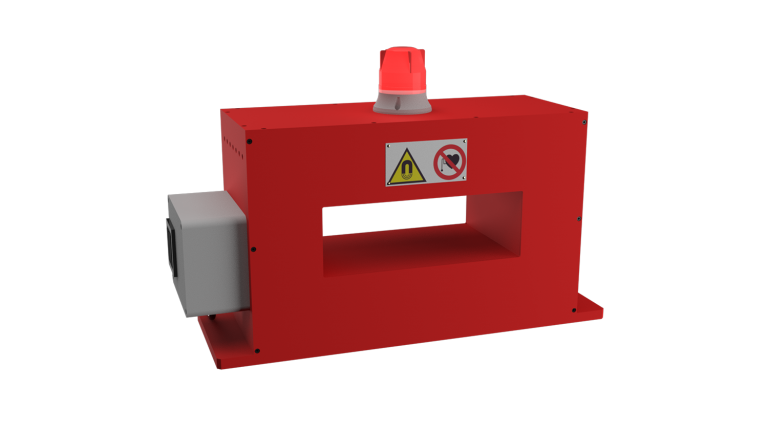

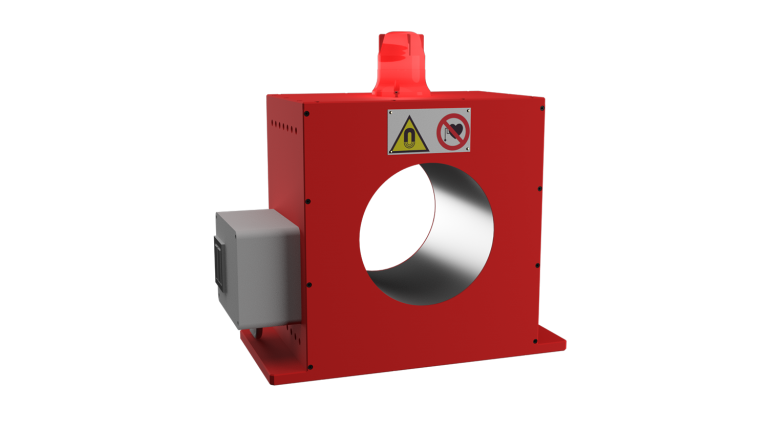

- Low frequency demagnetizers

- Mini gaussmeter

- Digital gaussmeter

- Electric pen with electronic regulation

MAGNETIC RESIDUAL

Workpieces made of ferromagnetic material can sometime show magnetic residual, that means low values of magnetism. There are many reason for this, and not only, as many people think, the holding or the manipulation with magnetic chucks or magnetic lifters. A lot of common machining operations can leave magnetic residual on workpieces: arc welding, induction hardening, EDM, MPI, but also common machining operation as turning, forging, bending can sometime leave magnetic residual.

Even if the values of magnetic residual is most of the time low and there are no effects in workpiece functionality sometimes they can be reason of problems (difficulty to make surface treatment or welding operations, metallic powder remaining on the surface with increasing of friction and wear).

SOLUTIONS

SPD propose many solution to eliminate this problem.

Our catalogue (that you can from the link here below) propose many demagnetization systems of different type and dimension.

They can eliminate magnetic residual also from the most difficult materials.

In our catalogue you can find also digital instruments useful to evaluate the residual and the effectiveness of the demagnetization process.