ELECTRO-PERMANENT GRINDING SYSTEM

Suitable for clamping work-pieces of any shape, size and thickness

on any type of grinding machine.

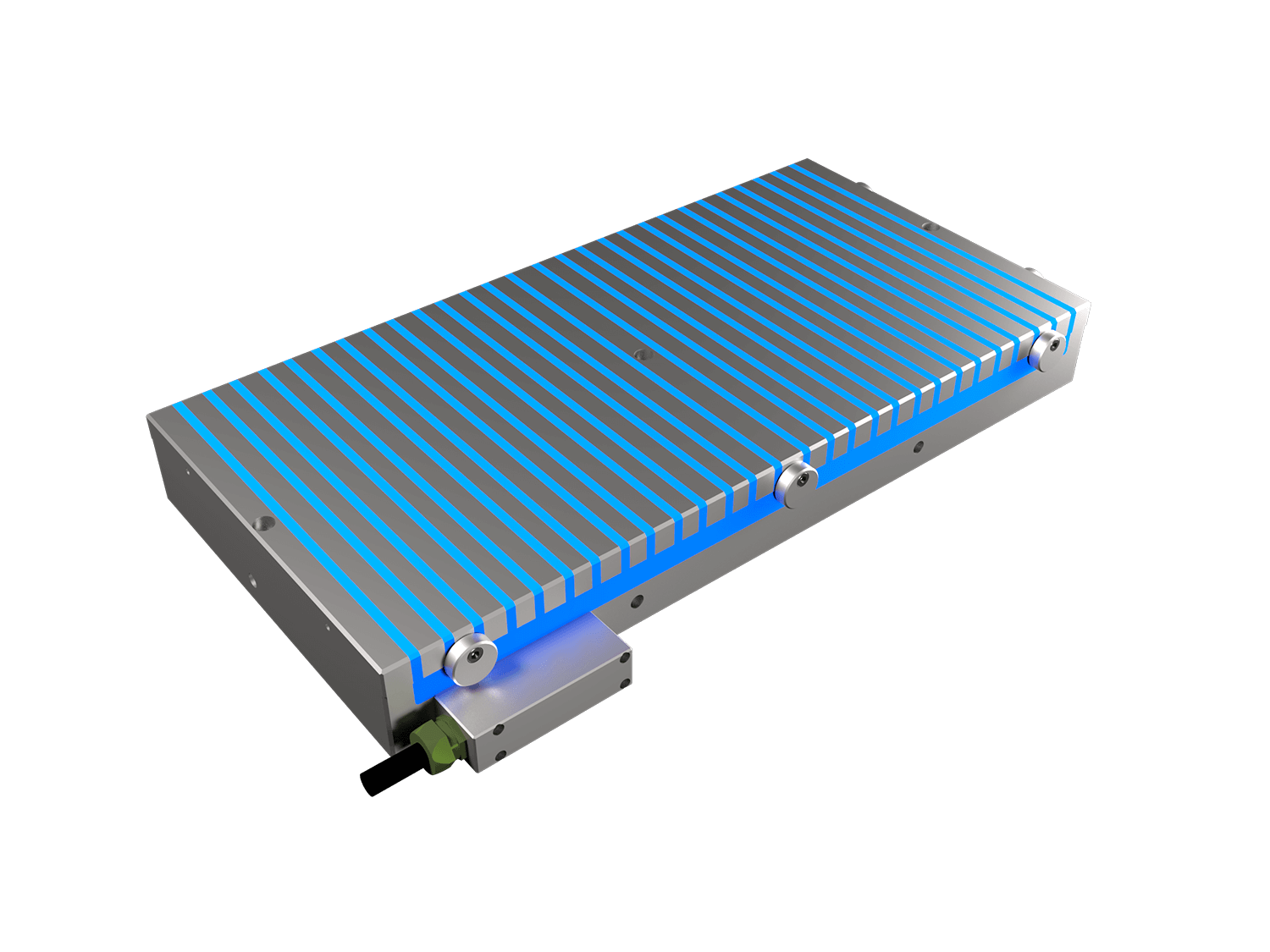

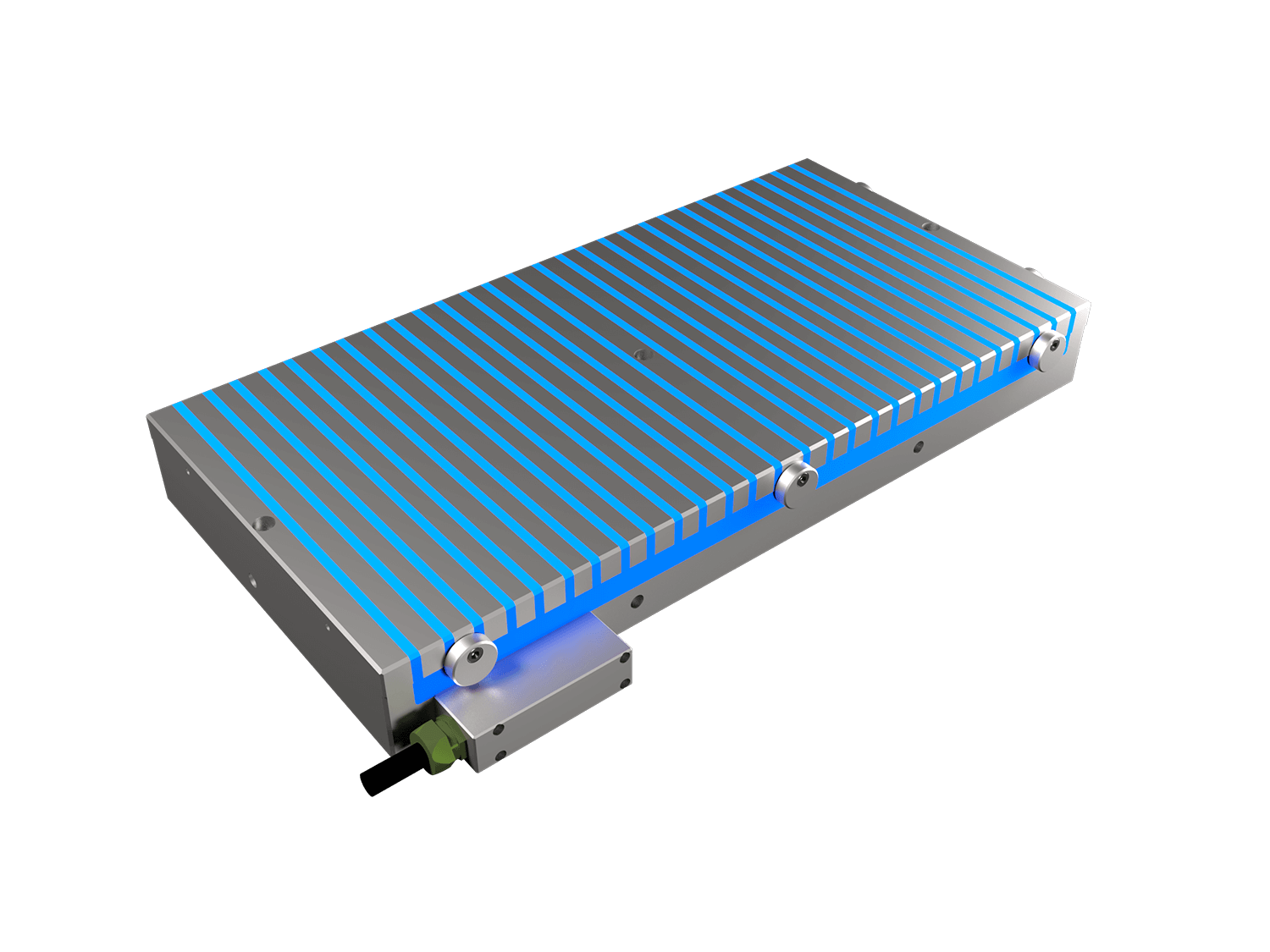

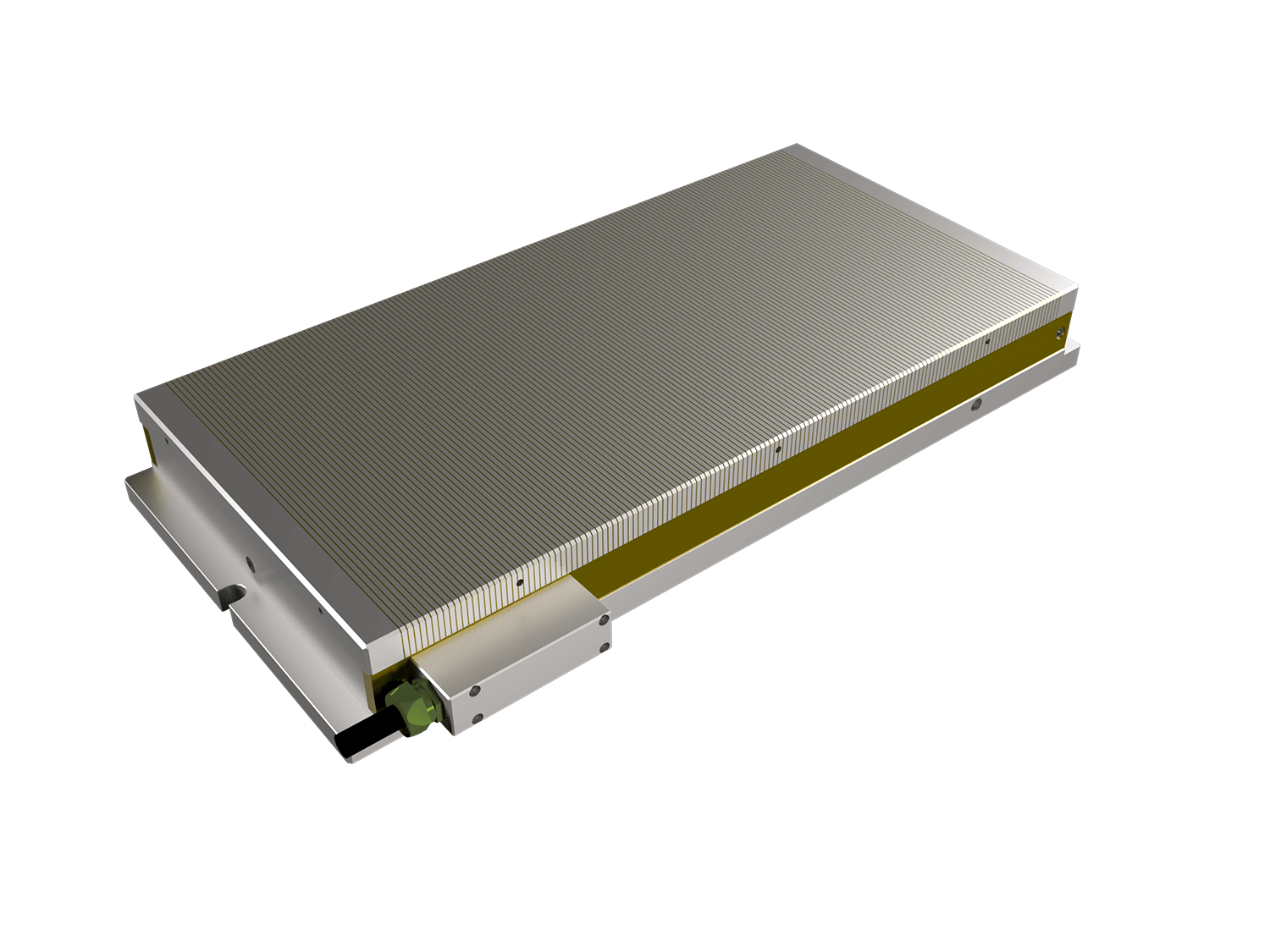

PM60A

ELECTRO-PERMANENT CHUCK FOR GRINDING OPERATIONS FEATURING A NO RESIDUAL DEMAG CYCLE AND STANDARD POLE PITCH WITH IRON AND RESIN STRUCTURE.

Recommended for medium-sized work-pieces with normal thickness (over 10 mm) suitable for common machining.

Not suitable for the machining of workpieces with thickness inferior to 4mm and dimensions smaller than 50x 50mm

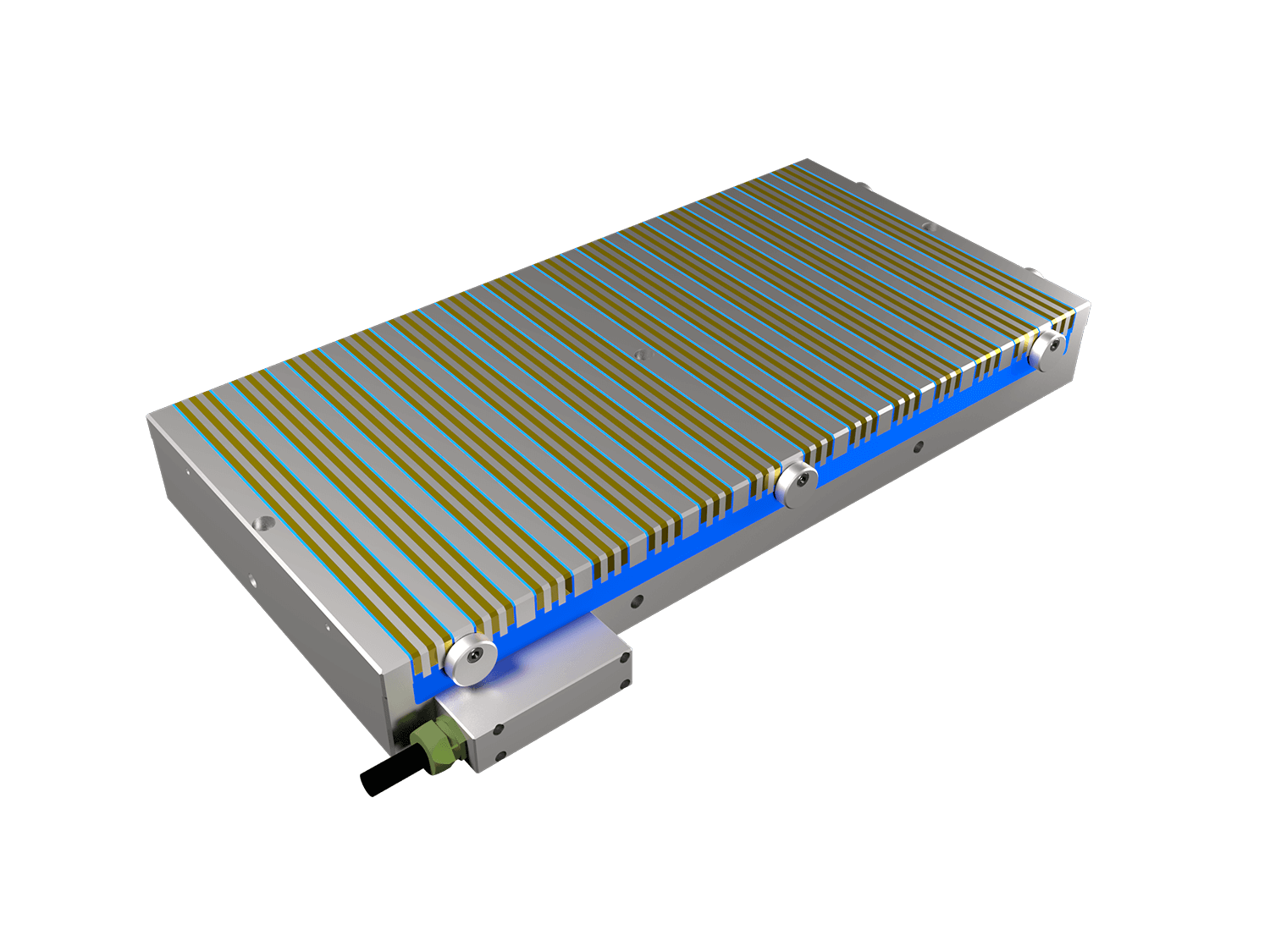

PM60D

ELECTROPERMANENT CHUCK FOR GRINDING OPERATIONS FEATURING A NO RESIDUAL DEMAG CYCLE AND FINE POLE PITCH WITH IRON AND BRASS STRUCTURE.

It represents the specific solution for thin-walled work-pieces (over 7 mm) and precision machining. Not suitable for the machining of workpieces with thickness inferior to 3mm and dimensions smaller than 50x 50mm

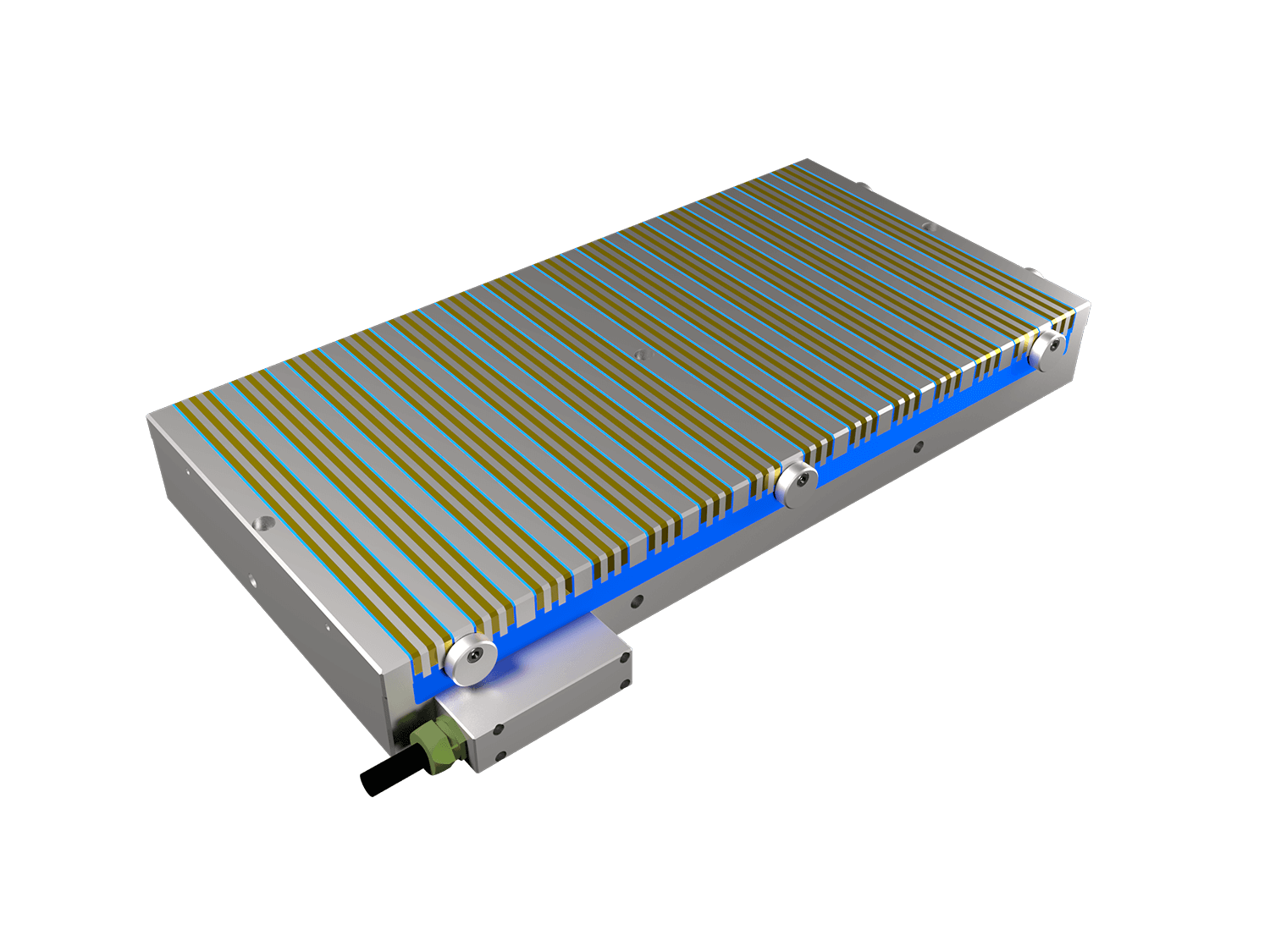

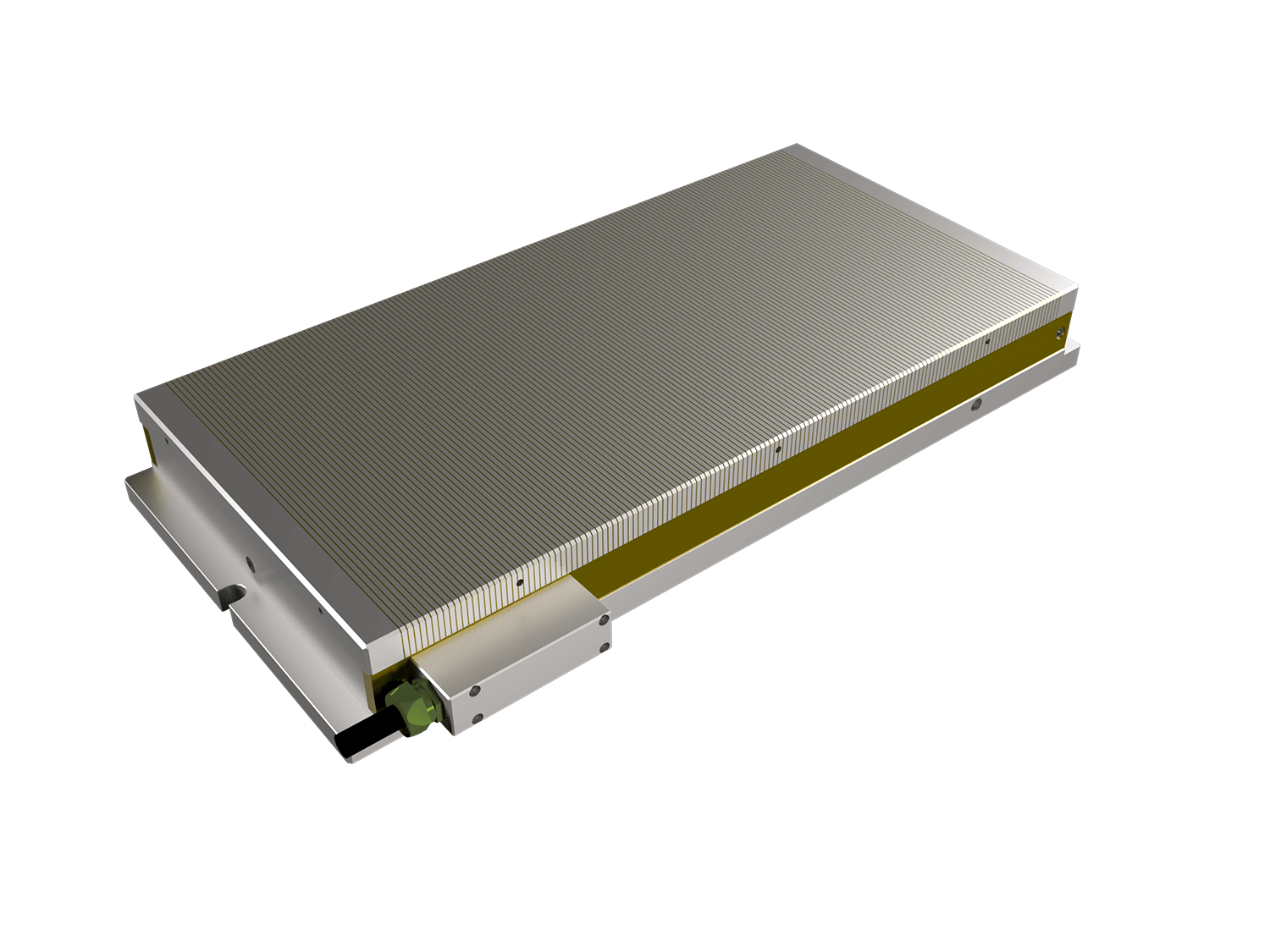

PM62

ELECTROPERMANENT CHUCK FOR GRINDING OPERATIONS FEATURING A NO RESIDUAL

DEMAG CYCLE AND AN ADDITIONAL UPPER PLATE OUT OF IRON AND BRASS.

The outstanding quality of this model lies in the upper plate, which is fixed on the magnetic chuck to ensure maximum rigidity. It is mainly used for high precision grinding and is able to clamp extremely well even very thin pieces thanks to its dense pole pitch ( over 5 mm). Not suitable for the machining of workpieces with thickness inferior to 2mm and dimensions smaller than 50x 50mm.

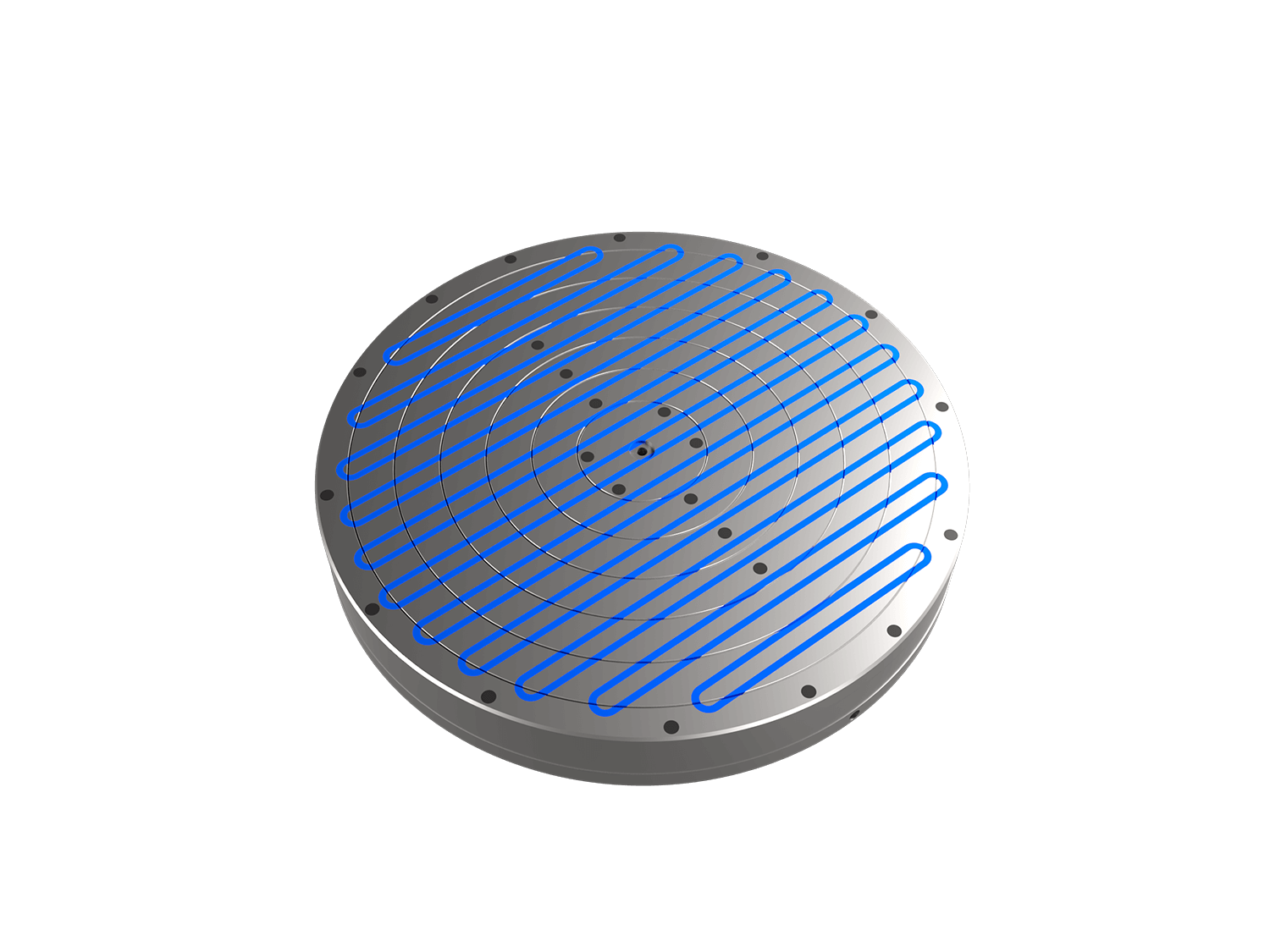

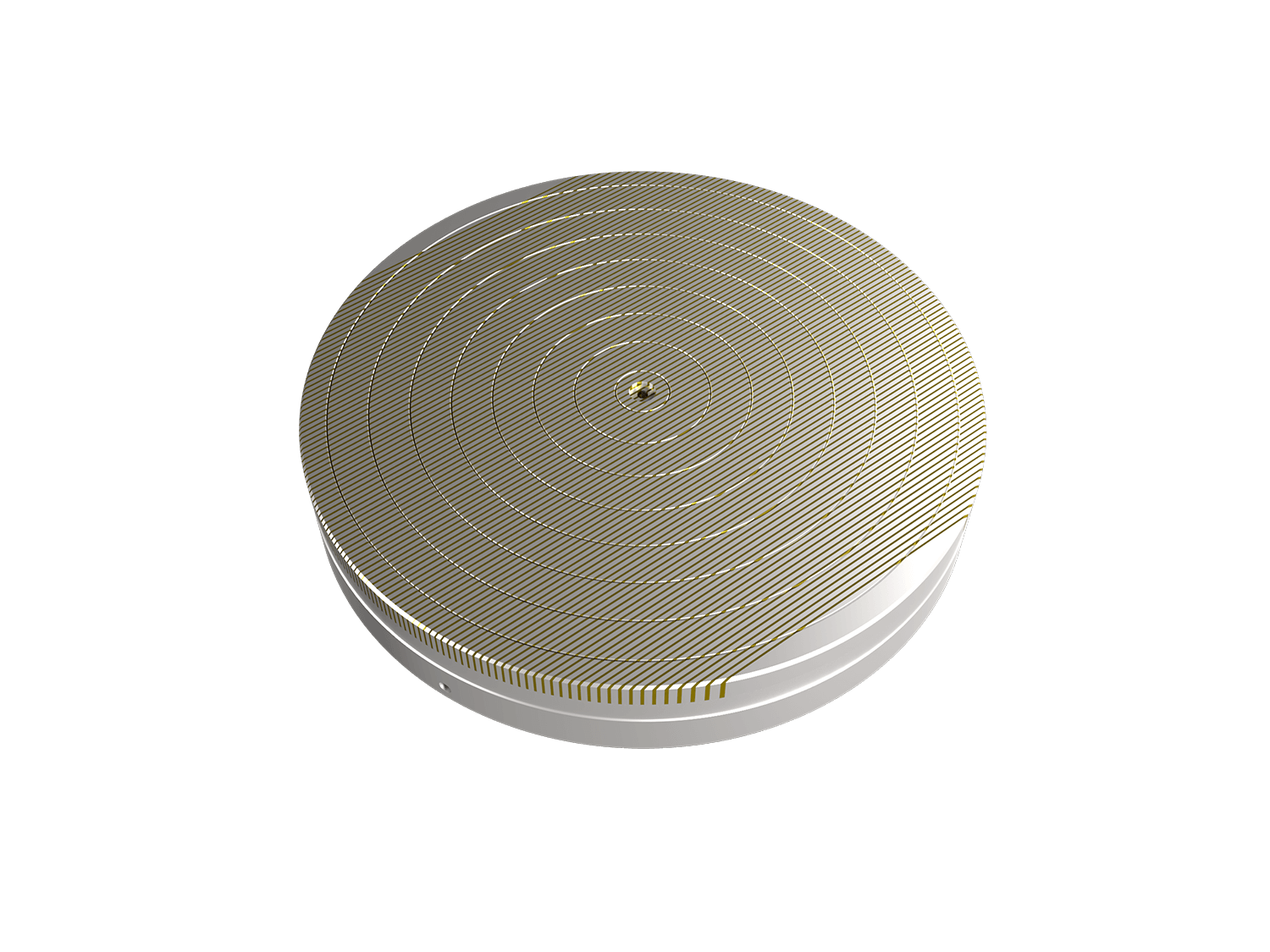

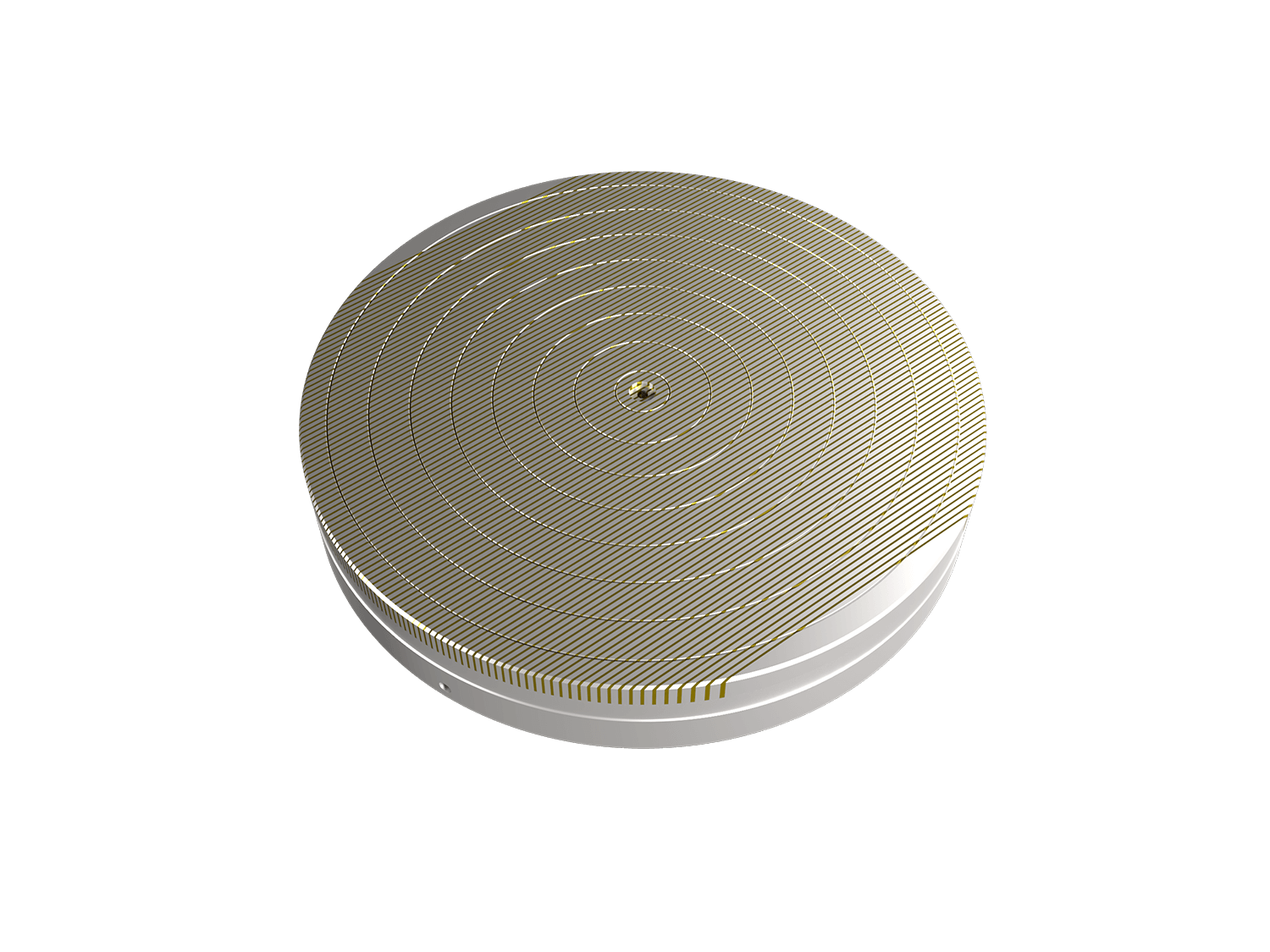

PM80A

CLOSED-POLE ELECTRO-PERMANENT CHUCK FOR CIRCULAR GRINDING, FEATURING A NO RESIDUAL DEMAG CYCLE AND POLE PITCH WITH IRON AND RESIN STRUCTURE.

Recommended for medium-sized workpieces with normal thickness (over 10 mm) suitable for circular machines. Not suitable for the machining of workpieces with thickness inferior to 4mm and dimensions smaller than 50x 50mm.

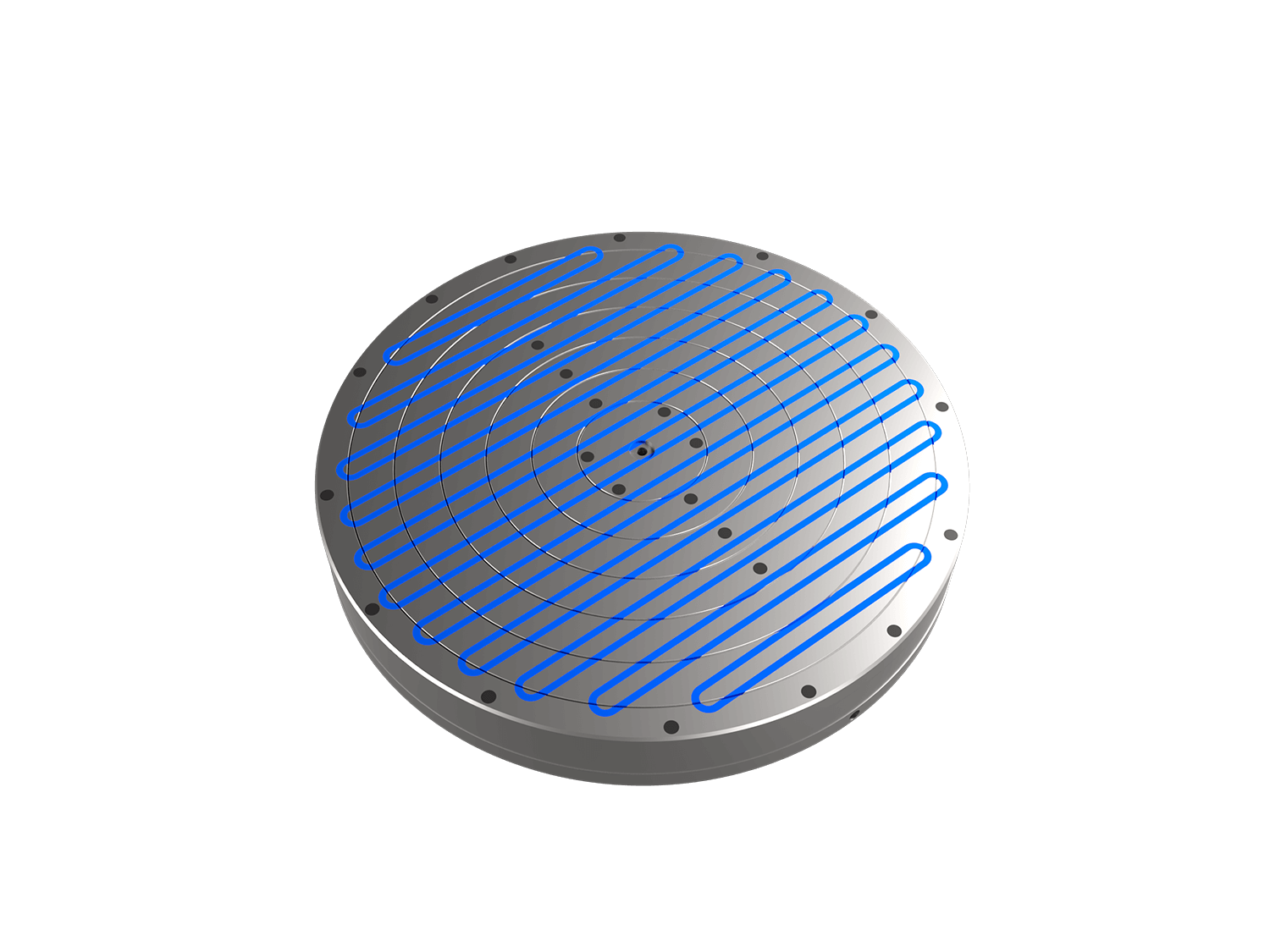

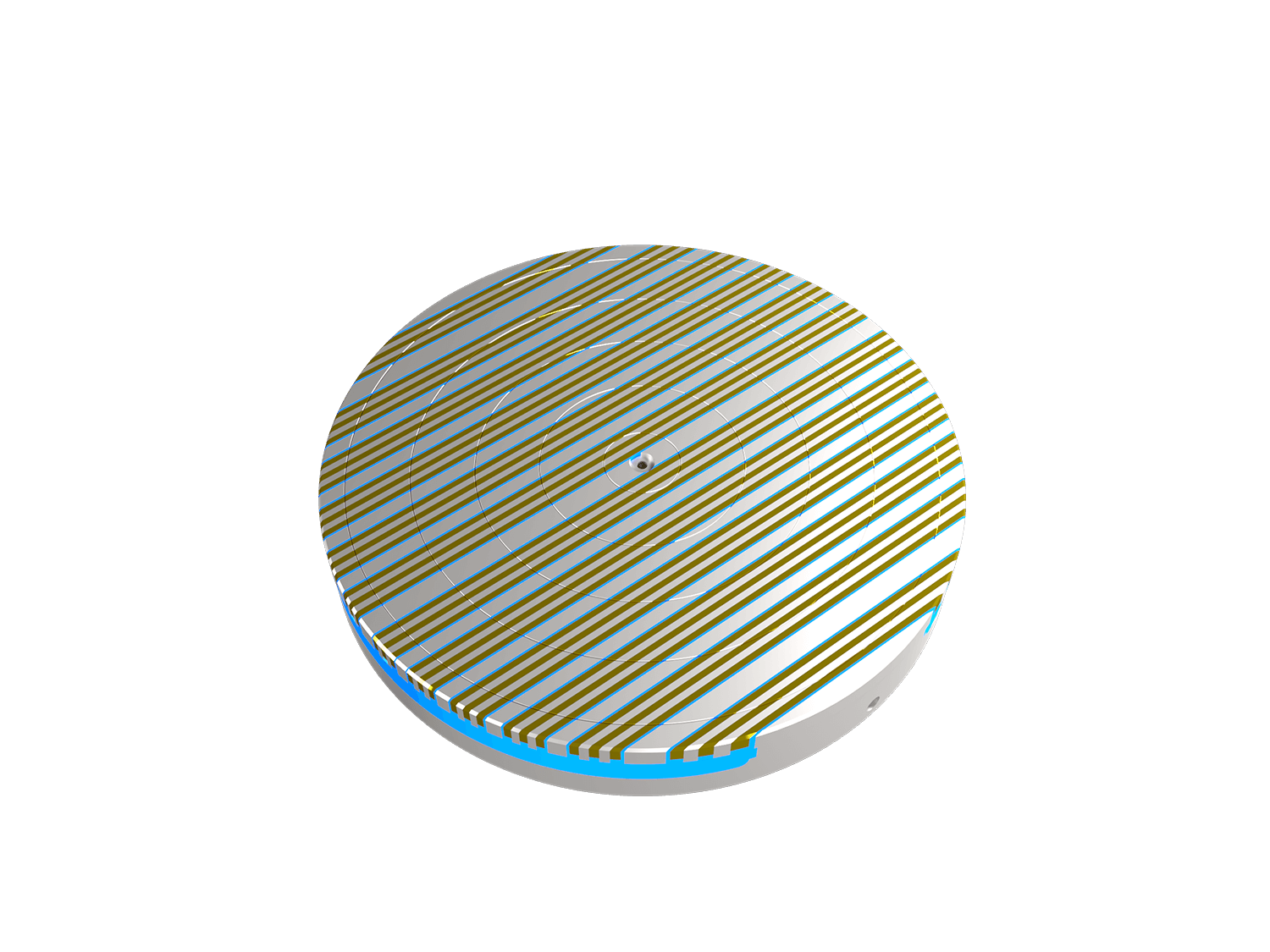

PM81D

OPEN-POLE ELECTRO-PERMANENT CHUCK FOR CIRCULAR GRINDING FEATURING A NO RESIDUAL DEMAG CYCLE AND POLE PITCH WITH IRON AND RESIN STRUCTURE.

It represents the specific solution for thin-walled work-pieces (over 7 mm) and precision circular machining. Not suitable for the machining of workpieces with thickness inferior to 3mm and dimensions smaller than 50x 50mm.

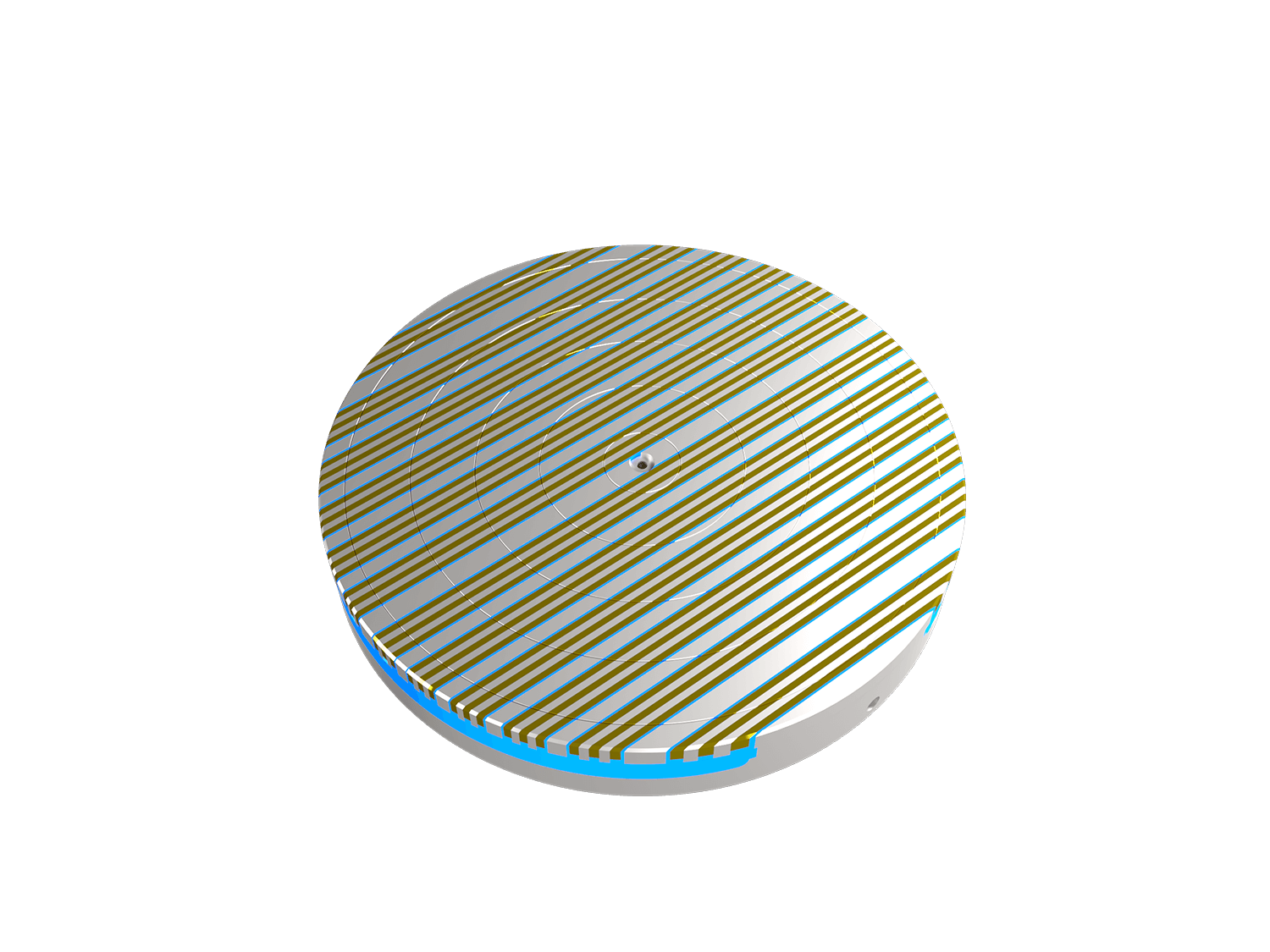

PM82

ELECTROPERMANENT CHUCK FOR CIRCULAR GRINDING OPERATIONS FEATURING A NO RESIDUAL DEMAG CYCLE AND AN ADDITIONAL UPPER PLATE OUT OF IRON AND BRASS

The outstanding quality of this model lies in the upper plate, which is fixed on the magnetic chuck to ensure stability. It is mainly used for high precision grinding and is able to clamp extremely well even very thin pieces thanks to dense pole pitch

(over 5 mm) on circular machines. Not suitable for the machining of workpieces with thickness inferior to 2mm and dimensions smaller than 50x 50mm.

ACCESSORIES

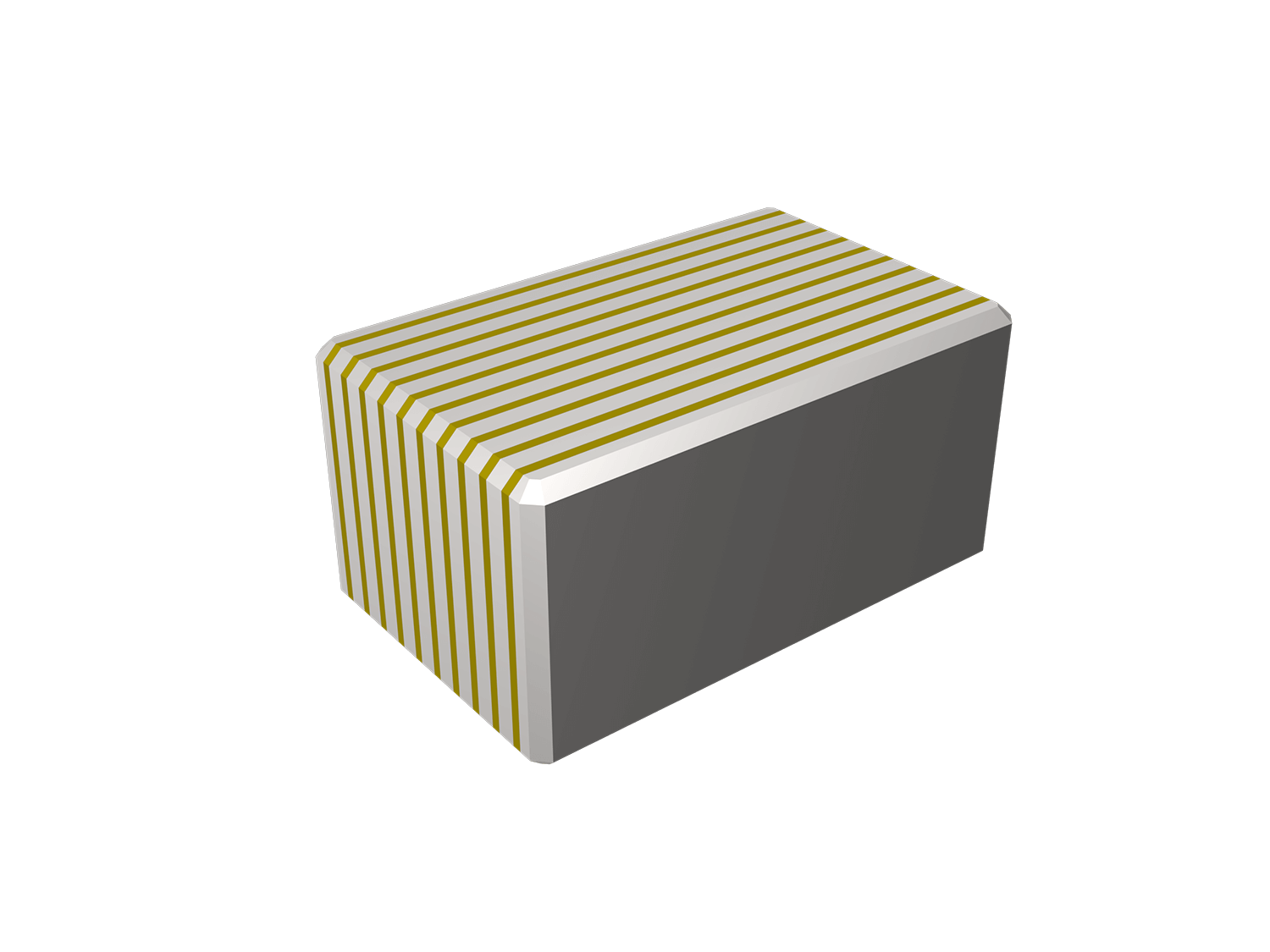

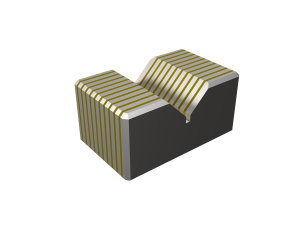

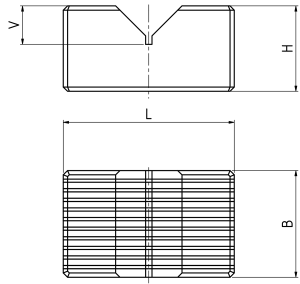

Laminated blocks

By placing these silver brazed blocks out of iron or brass onto the magnetic chuck, the flux is directly transferred to the workpiece to be machined.

| MODEL | DIMENSIONS | WEIGHT [kg] | |||

| B [mm] | L [mm] | H [mm] | V [mm] | ||

| BL10.50080 | 50 | 80 | 40 | - | 2,6 |

| BL10.50100 | 50 | 100 | 40 | - | 3,2 |

| BL20.50080 | 50 | 80 | 40 | 16 | 2,4 |

| BL20.50100 | 50 | 100 | 40 | 16 | 3 |

| BL30.85250 | 85 | 250 | 50 | - | 9 |

| BL30.85500 | 85 | 250 | 50 | - | 18 |

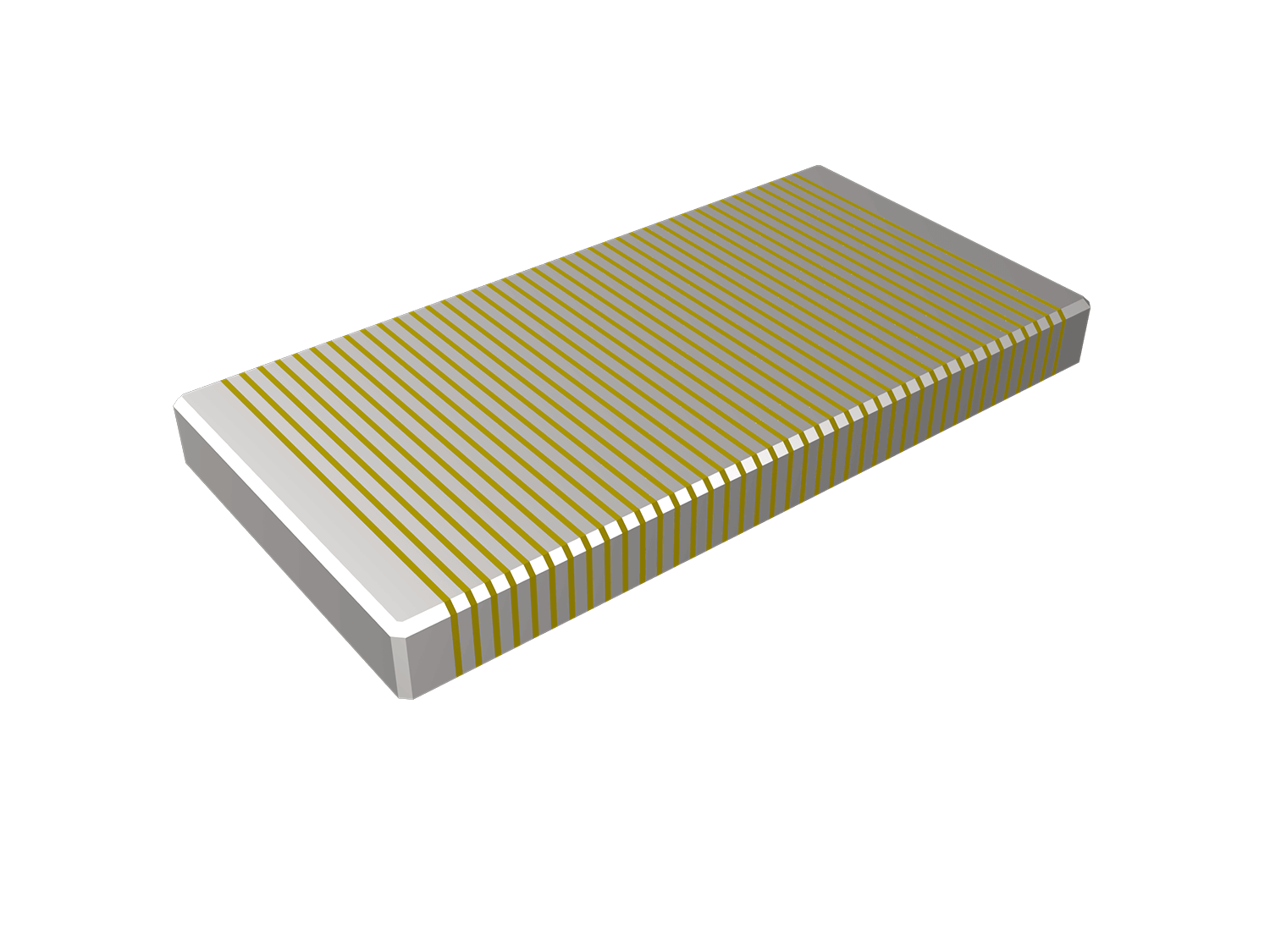

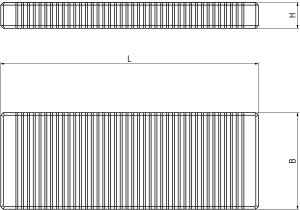

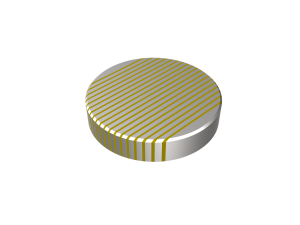

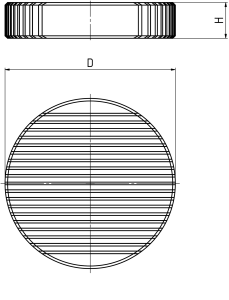

Additional plates

By placing these silver brazed plates out of iron or brass onto the magnetic chuck, the flux is directly transferred to the workpiece to be machined.

The polarity of both plates and chuck has to be aligned in the same direction.

| MODEL | DIMENSIONS | WEIGHT[kg] | |||

| B [mm] | L [mm] | D [mm] | H [mm] | ||

| PS10.10020 | 100 | 200 | 21 | 3,6 | |

| PS10.12020 | 130 | 250 | 21 | 5,8 | |

| PS10.15030 | 150 | 300 | 21 | 8,1 | |

| PS10.15035 | 150 | 350 | 21 | 9,4 | |

| PS10.20040 | 200 | 400 | 21 | 14,3 | |

| PS10.20050 | 200 | 500 | 21 | 18 | |

| PS20.00100 | 100 | 21 | 1,4 | ||

| PS20.00150 | 150 | 21 | 3,2 | ||

| PS20.00200 | 200 | 21 | 5,6 | ||

| PS20.00300 | 300 | 21 | 12,6 | ||

| PS20.00400 | 400 | 21 | 22,5 | ||

| PS20.00500 | 500 | 21 | 35 | ||