IMPORTANCE OF THE POLE PITCH

The real reason for choosing a magnetic chuck over another lies

in the ideal pole pitch for the work-piece to be magnetised.

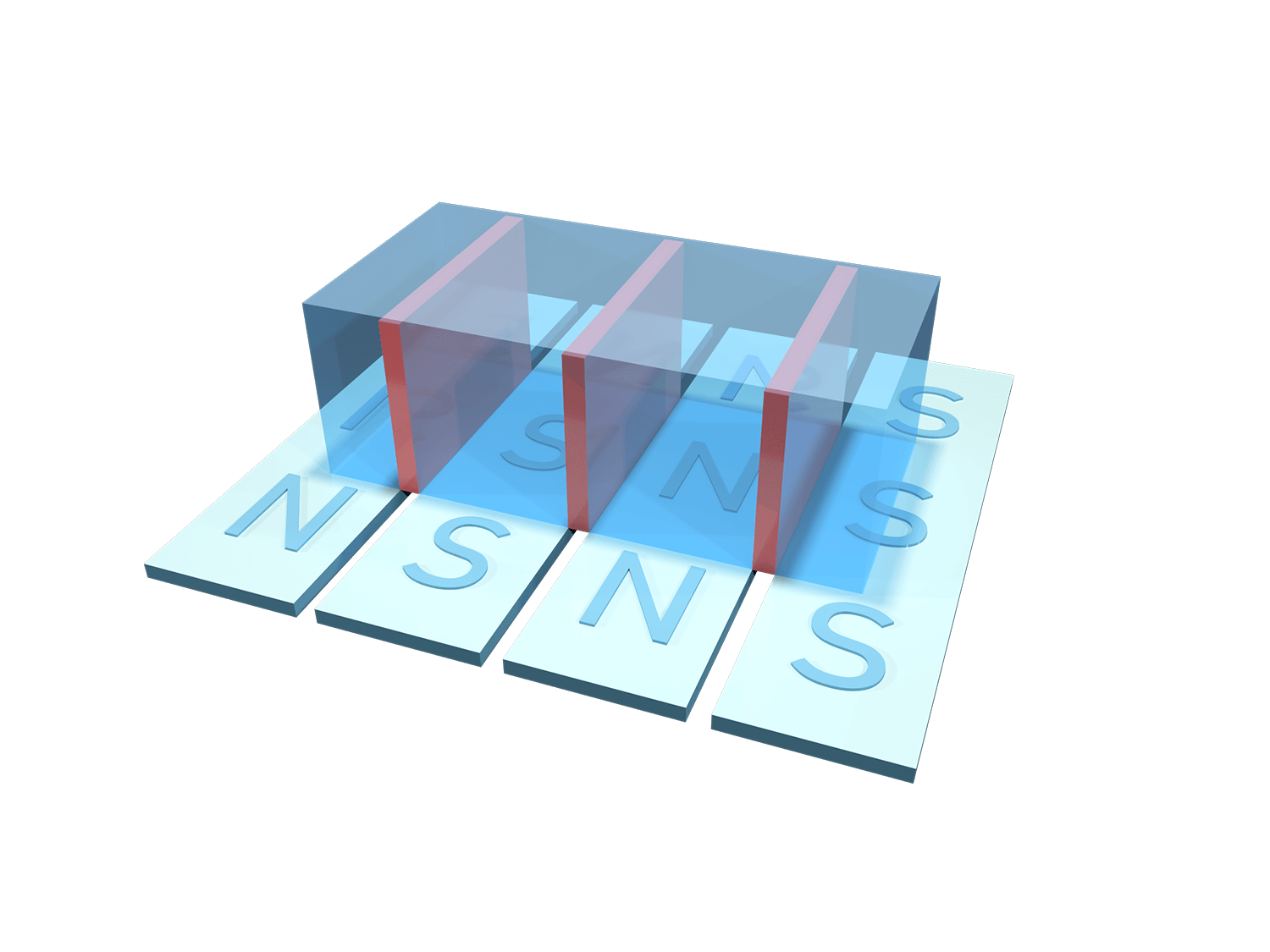

POLE AND COUNTER-POLE TECHNOLOGY

This technology is based on an active pole underneath of which an alnico magnet with coil, spool and an iron counter-pole (or induced pole) is placed, forming part of the chuck frame. The main advantage is the possibility of having narrow pole pitches and rigid structures that can easily be fastened to the machine bed.

PARALLEL POLES ARRANGEMENT

The longitudinal poles are laid out parallelly, alternating between north and south polarities. The magnets arranged this way generate the clamping force when activated. Activation occurs by using an electronic control device, and its duration is less than one second. The magnetic module will then remain active for as long as necessary, without additional use of energy.

TYPE “A” POLE

Suitable for common grinding operations, optimal for thicknessesover 10 mm.

TYPE “D” POLE.

Suitable for precision work machining on thicknessesover 7 mm.