ELECTRO-PERMANENT MILLING SYSTEM

It allows milling, boring and drilling operations on pieces of various shapes and sizes, reducing clamping times and obtaining high precision.

The magnetic chuck for milling operations, thanks to the electro-permanent technology, does not overheat, does not deform and does not suffer from interruptions in the power supply.

It can be activated in a fraction of a second and with a single input of energy, generating a homogeneous, stable and permanent force field. The work-piece remains safely clamped even after the control unit has been disconnected.

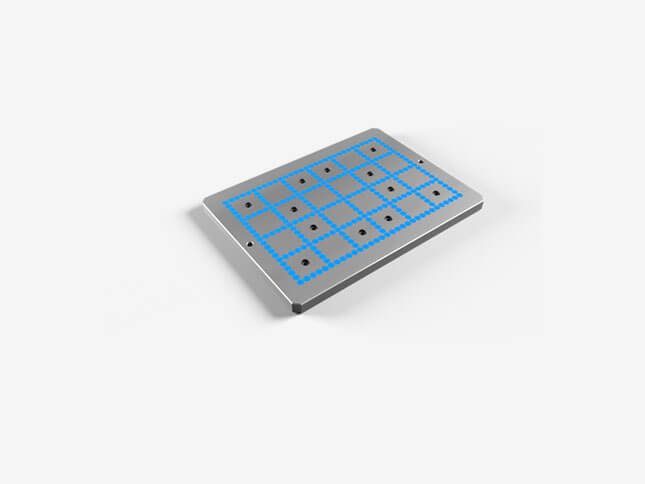

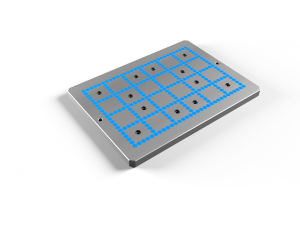

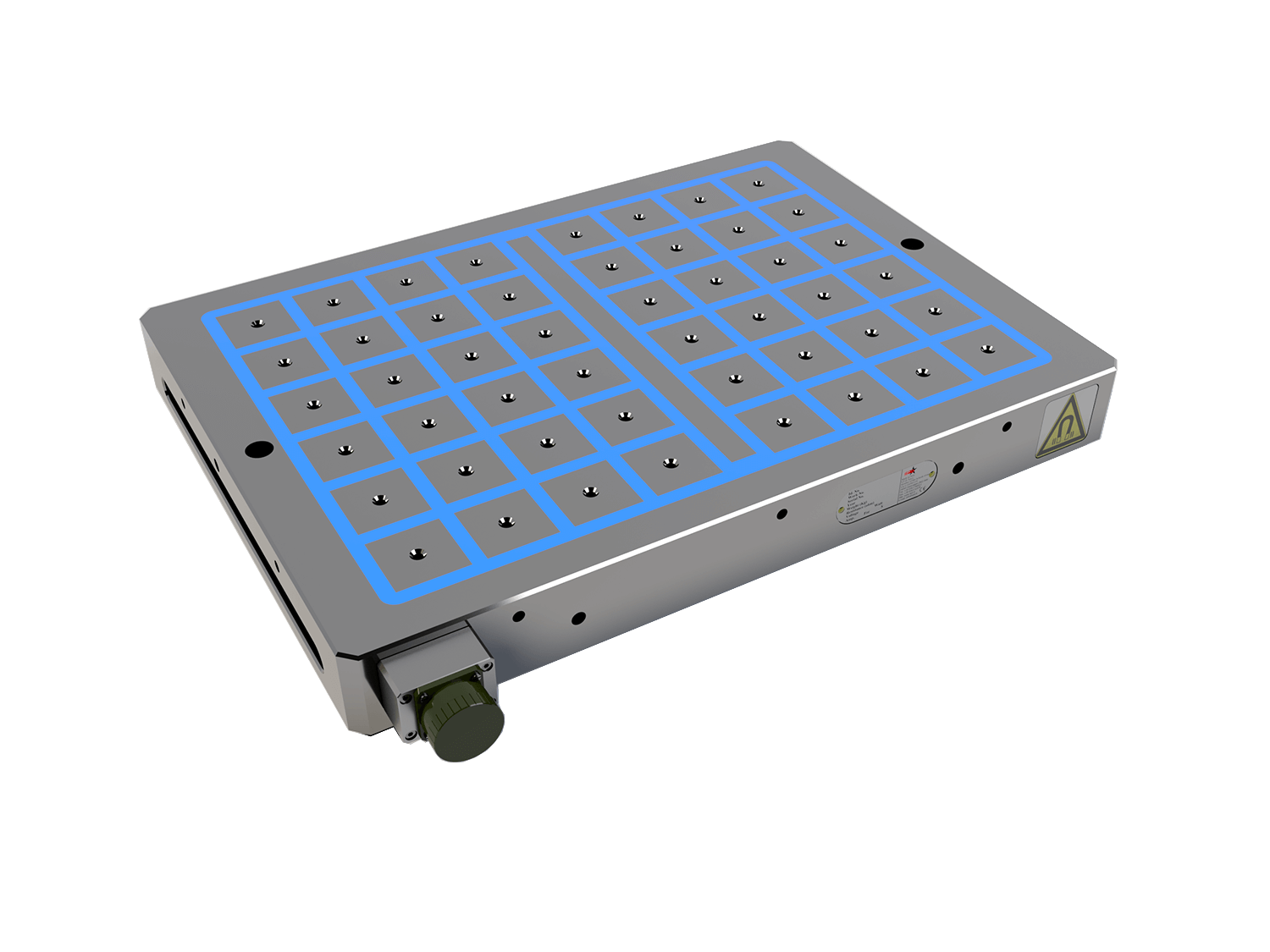

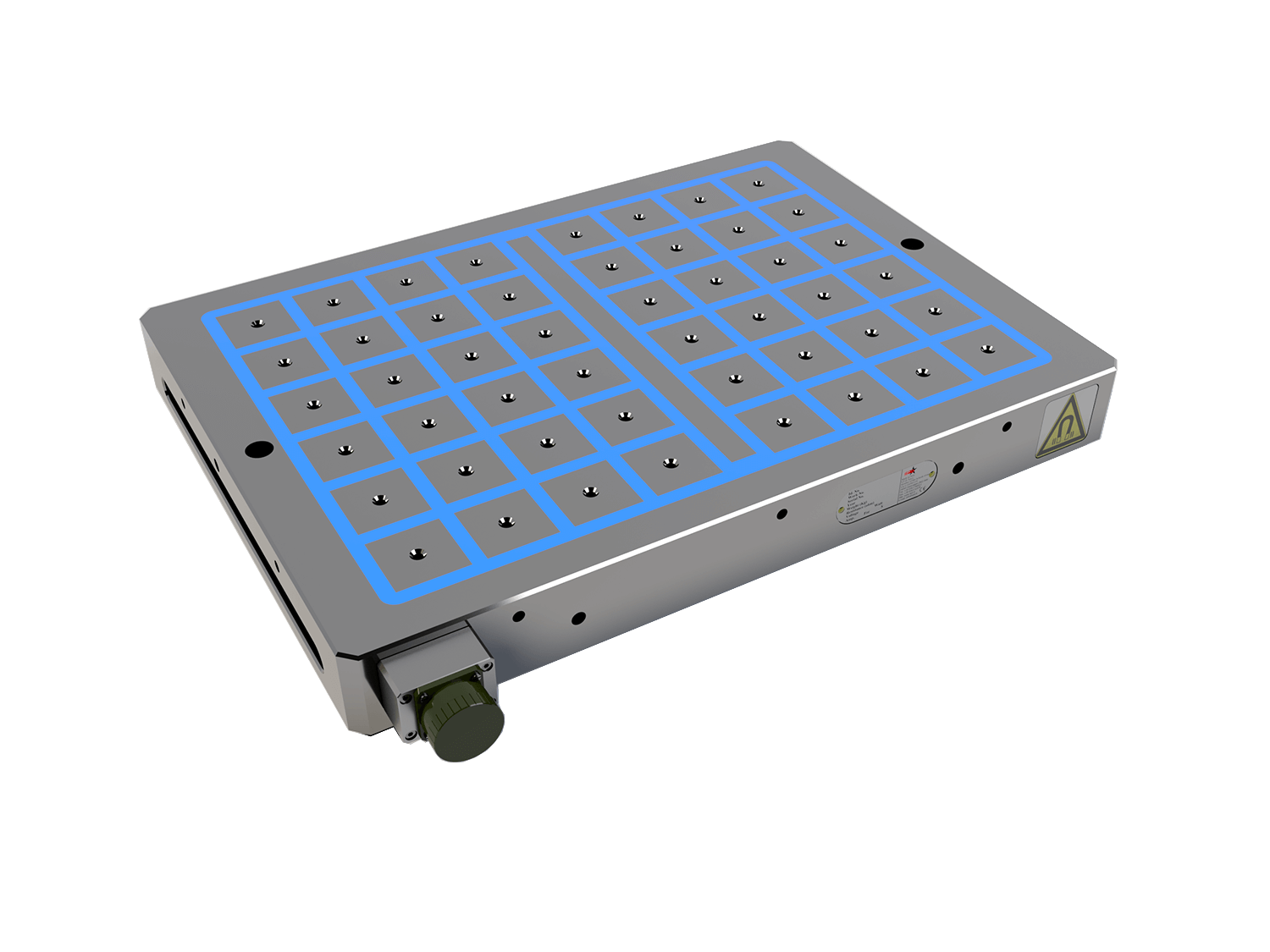

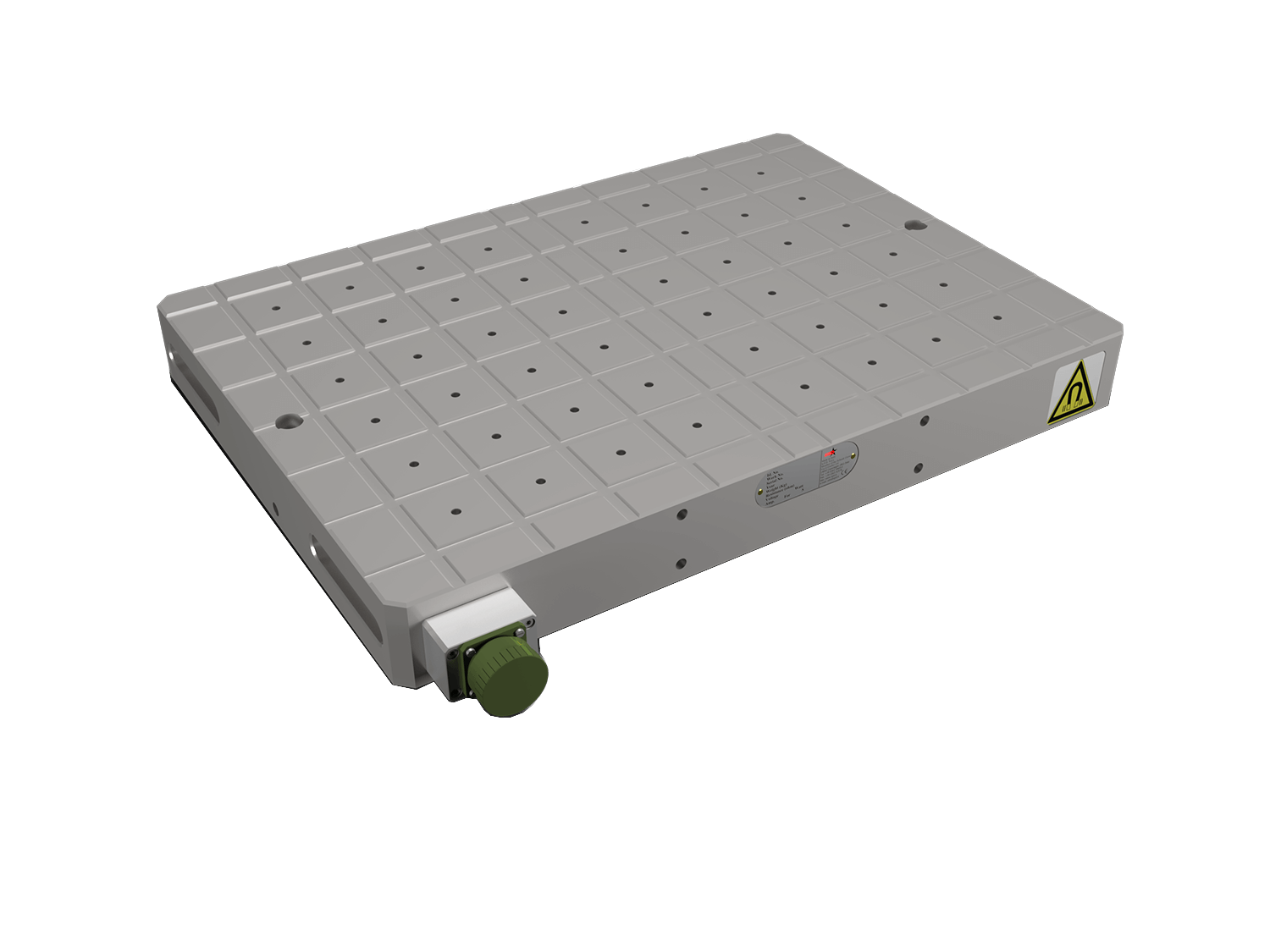

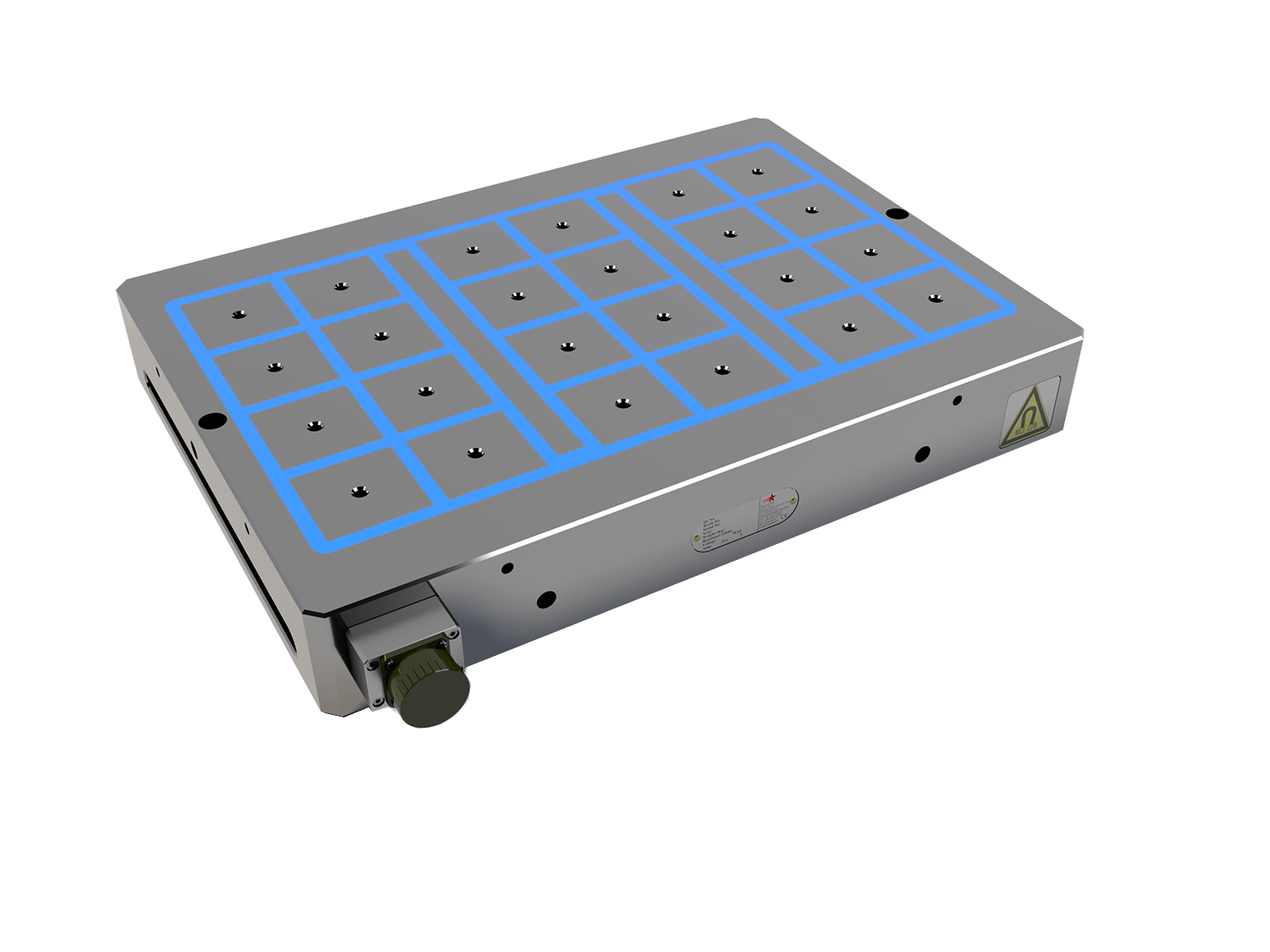

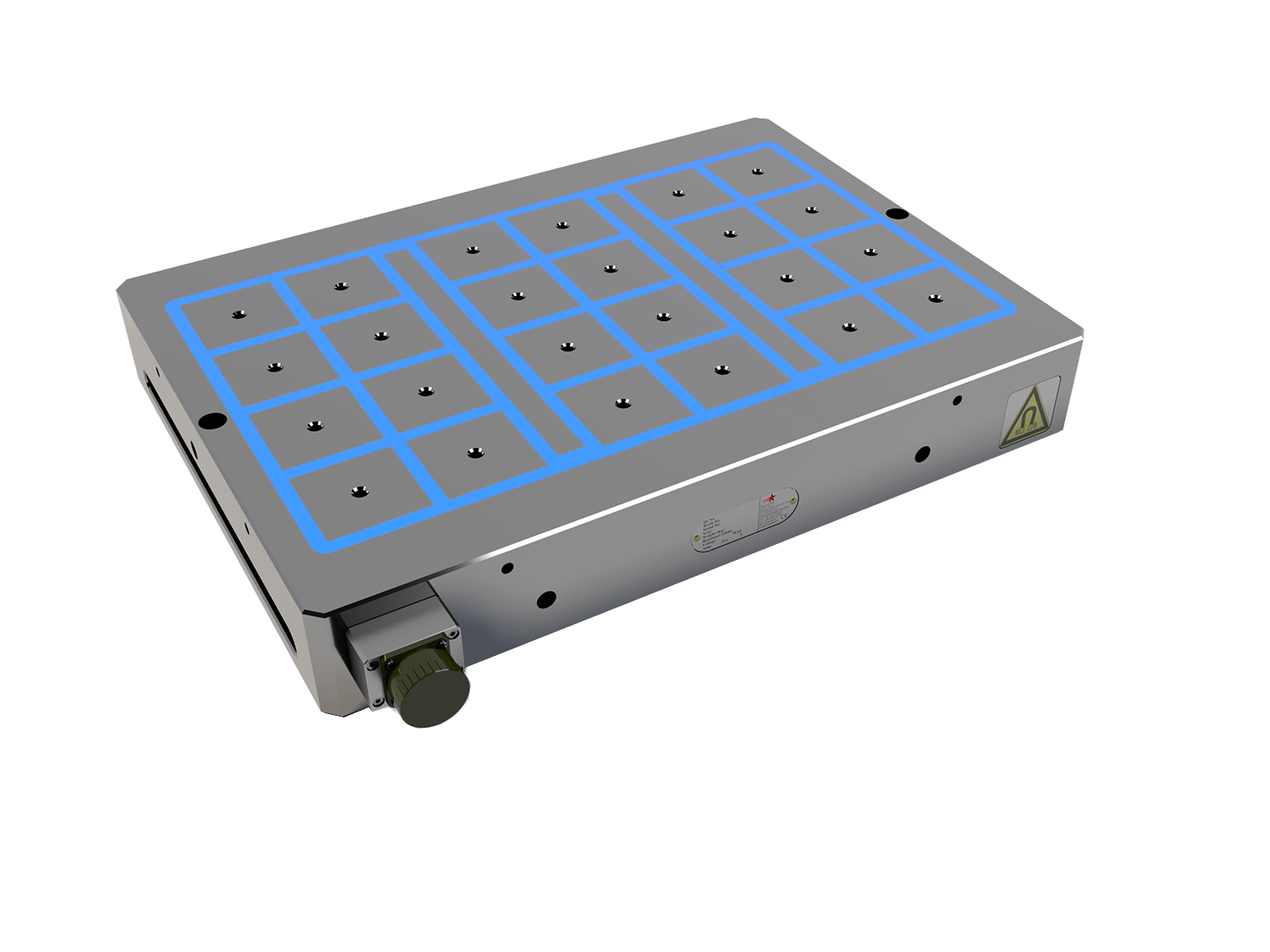

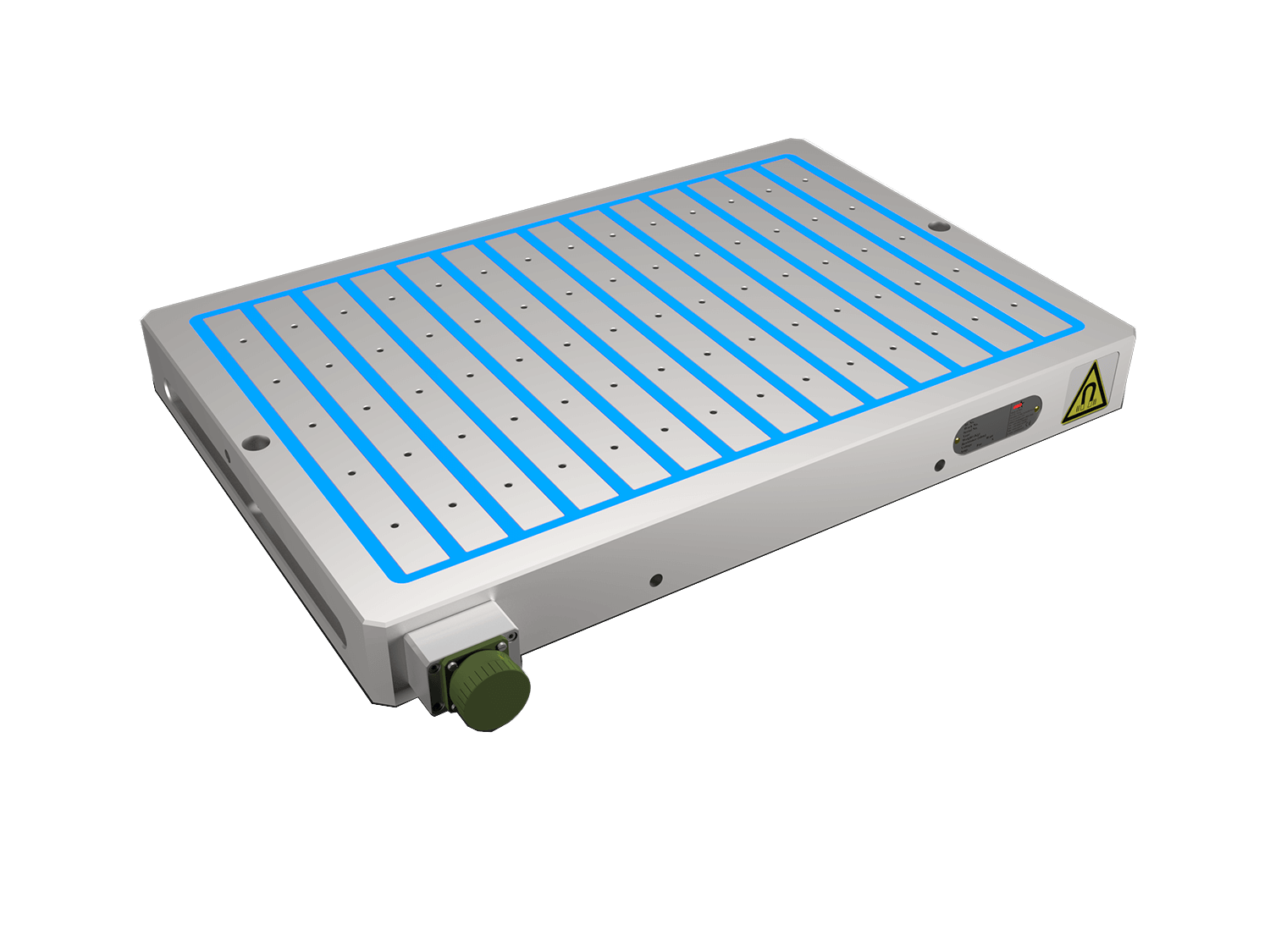

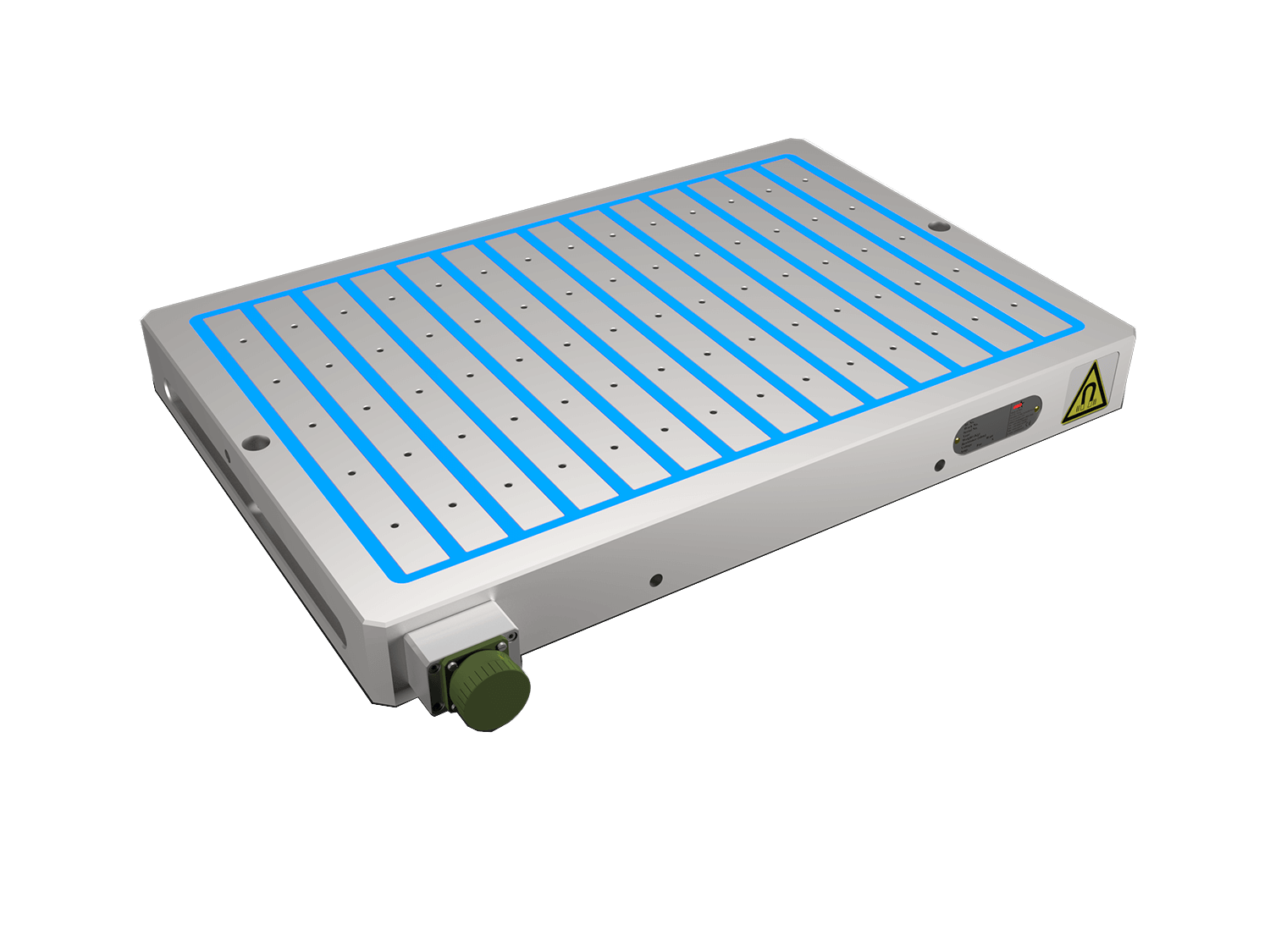

MFR-A1-050

ELECTRO-PERMANENT CHUCK FOR REMOVAL THROUGH MILLING ON MEDIUM-LOW THICKNESS PIECES

It is the most versatile magnetic chuck in the range. Generating force on few millimetres, it enables small and medium-sized workpieces with reduced thicknesses to be processed. The dense pole pitch allows effective adaptation to a wide range of designs.

It can be used with fixed and mobile extensions, for processing on 5-axis machines, with both unfinished and finished work-pieces.

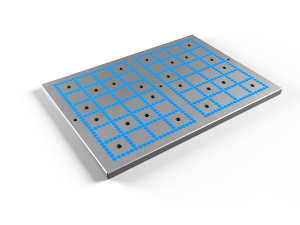

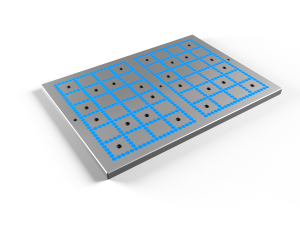

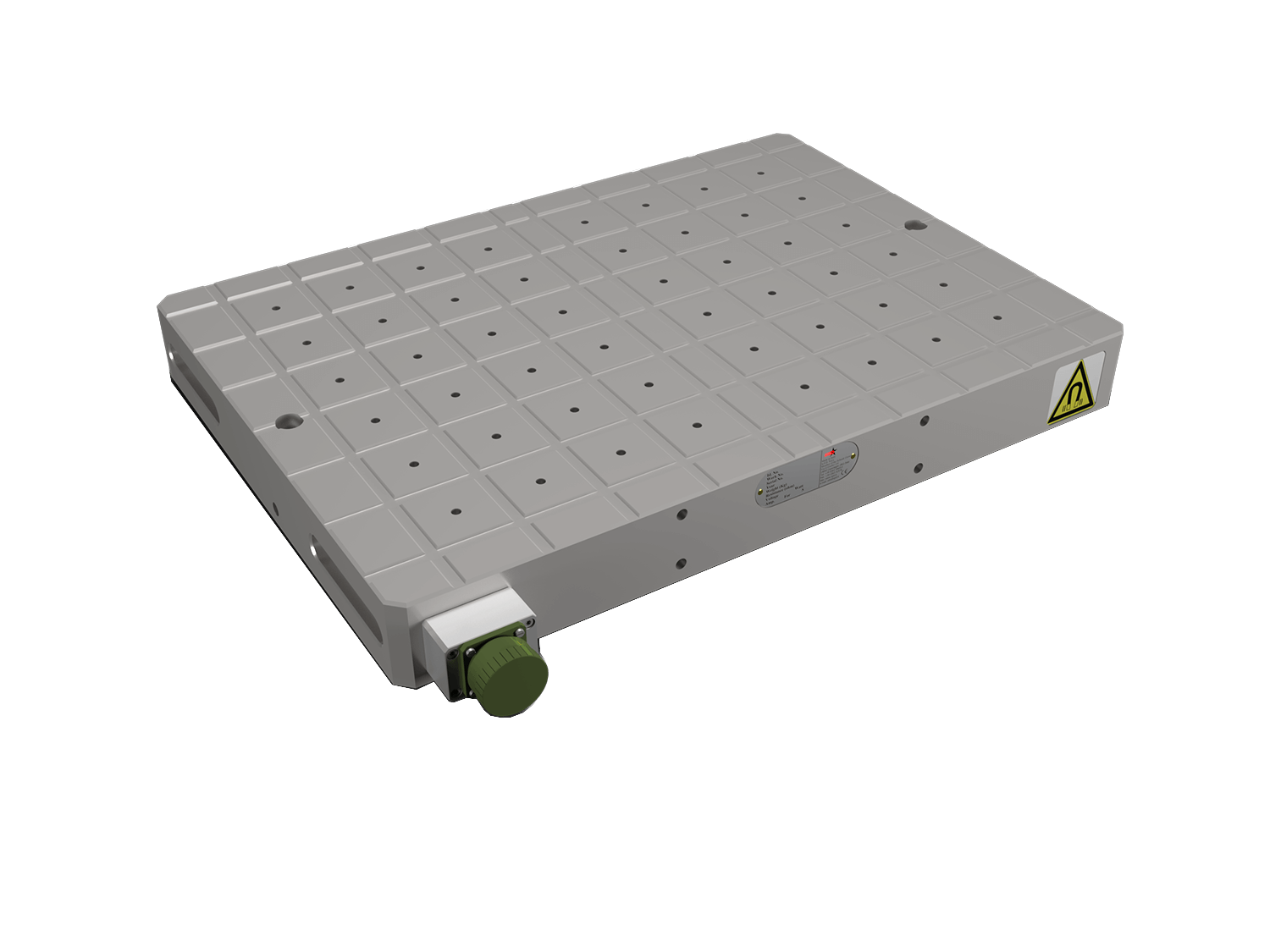

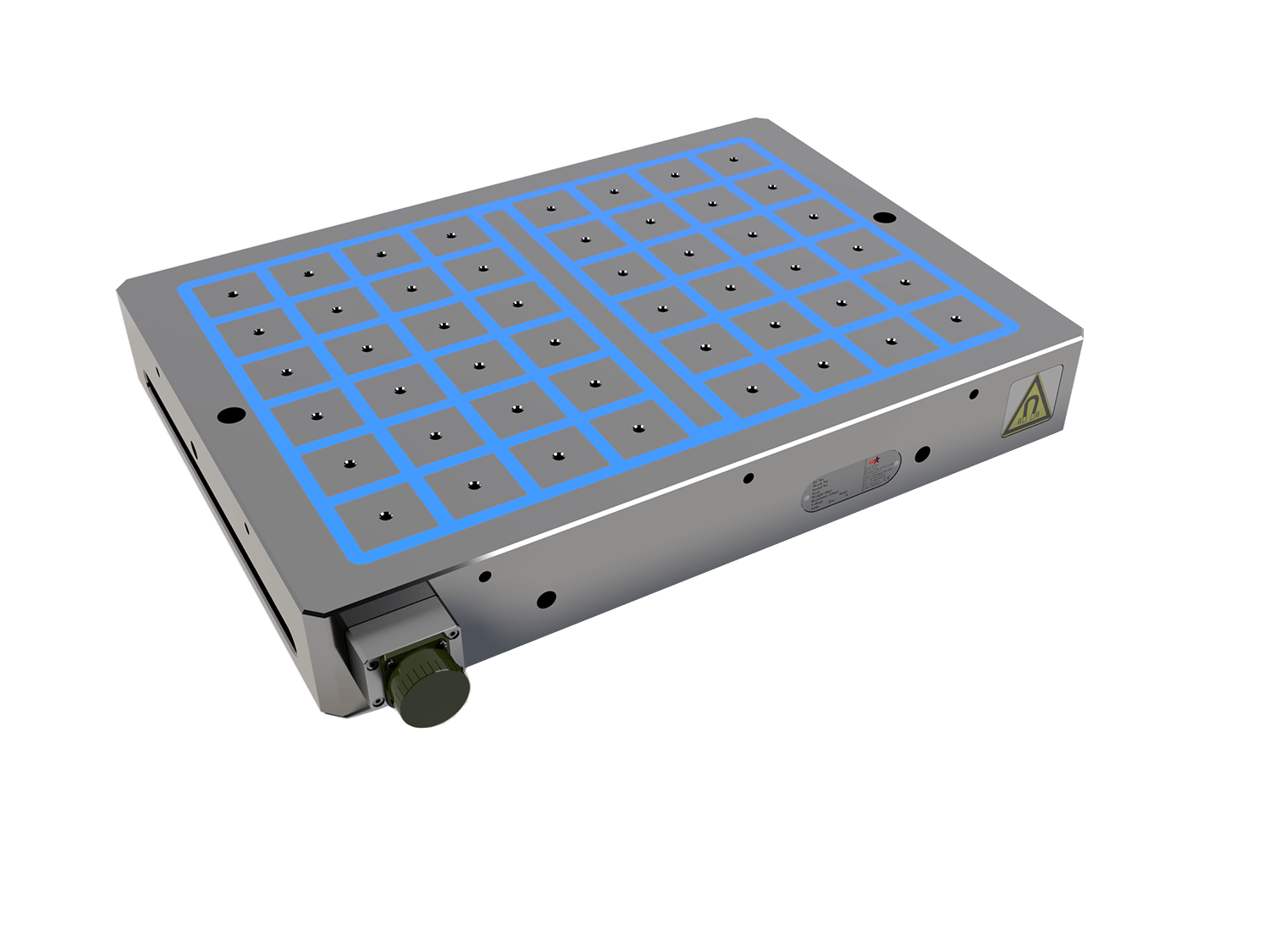

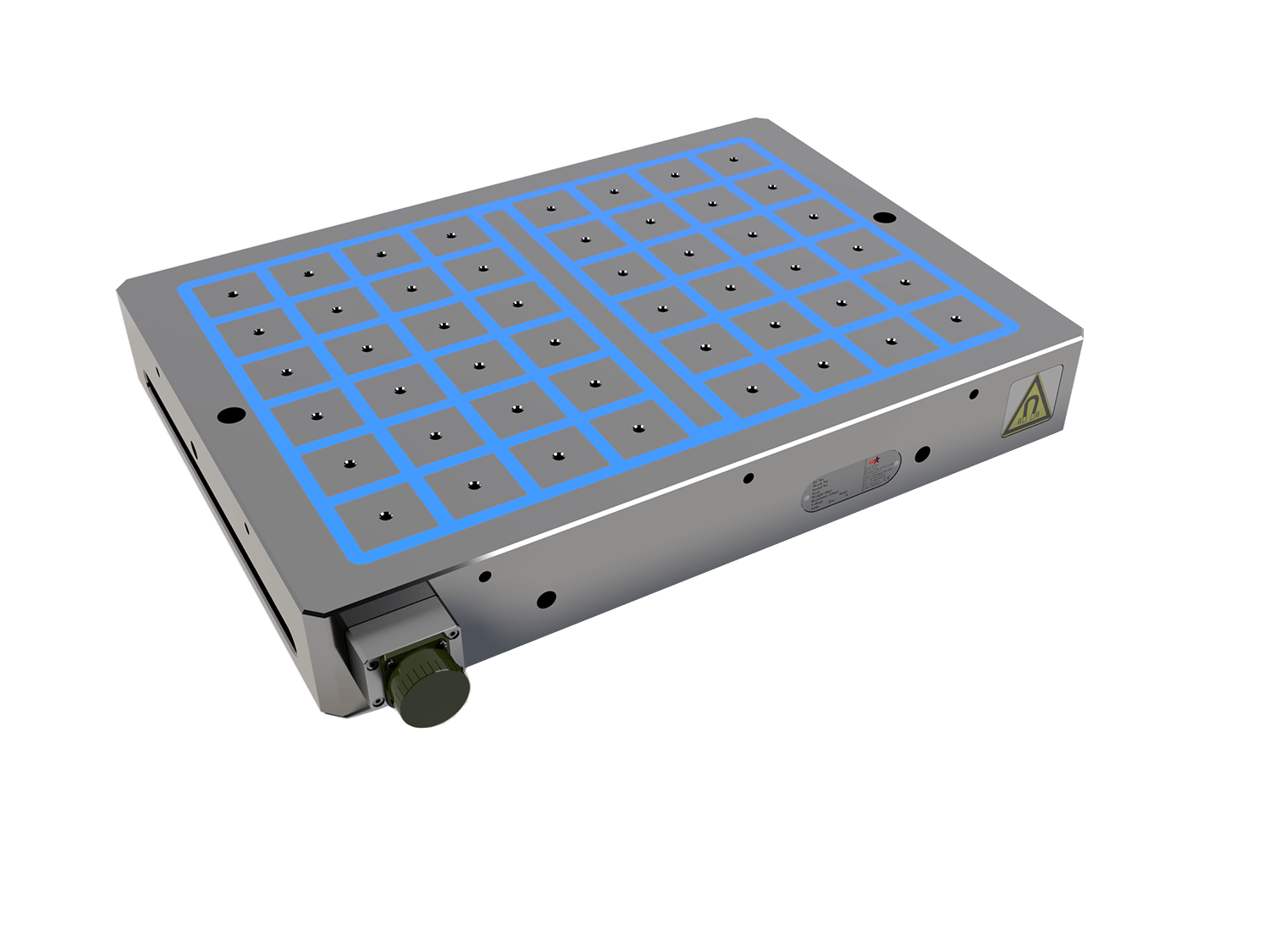

MFS-A1-050

ELECTRO-PERMANENT CHUCK WITH SQUARE POLE LAYOUT, WITH FULL STEEL CLAMPING SURFACE, DESIGNED FOR HARSH MACHINING OPERATIONS AND AGGRESSIVE ENVIRONMENTS.

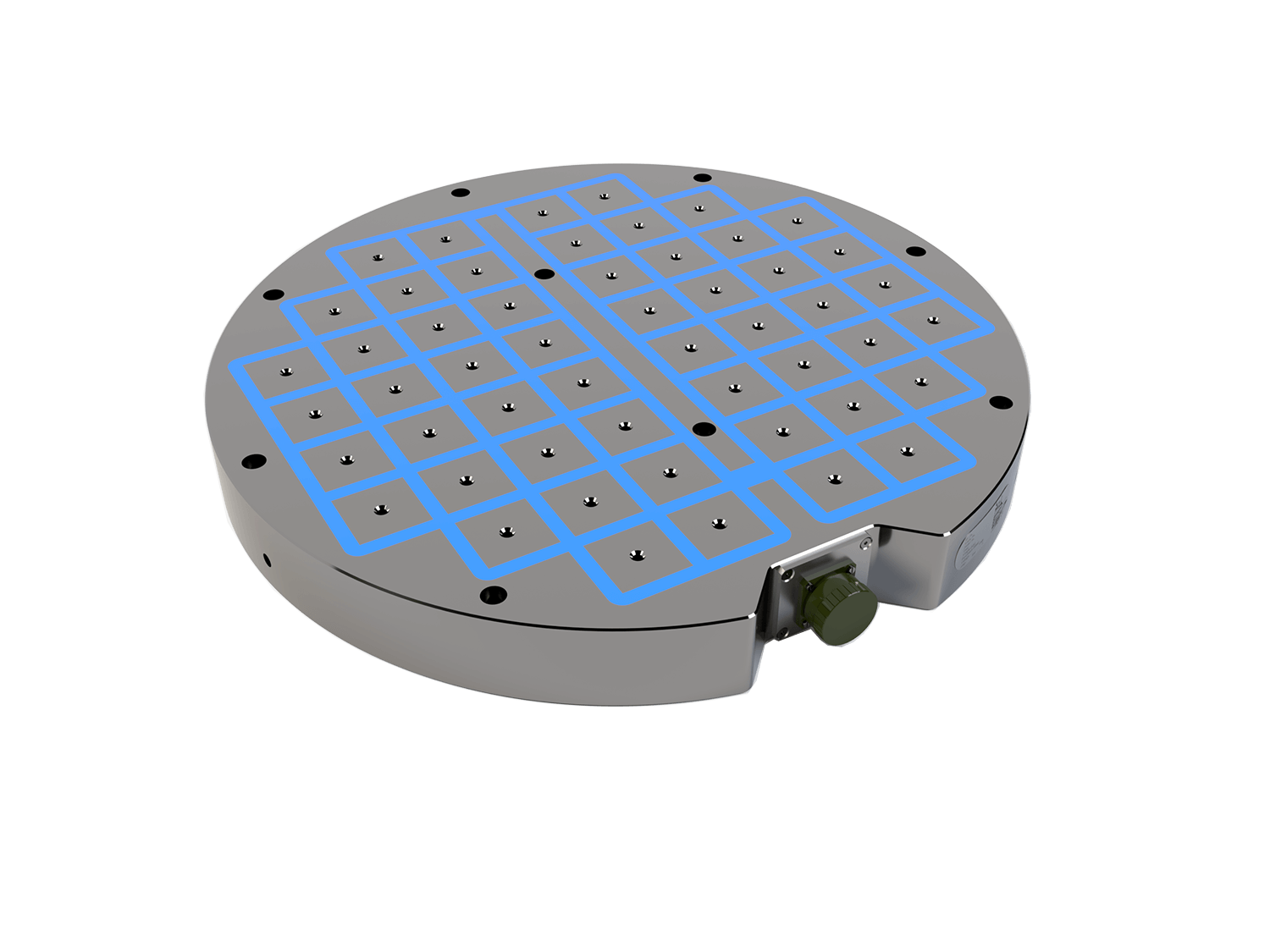

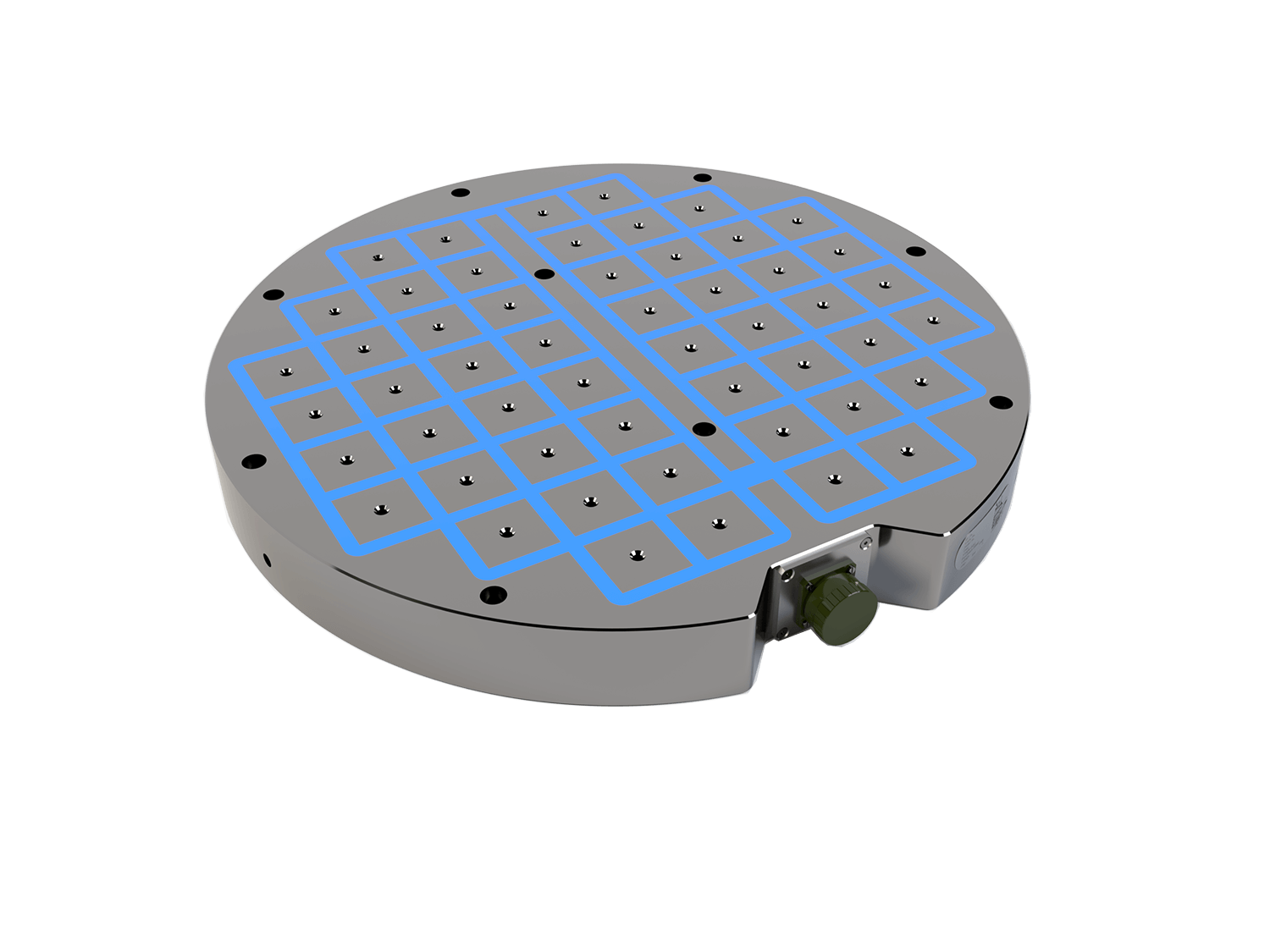

MFR-A1-050

CIRCULAR ELECTRO-PERMANENT CHUCK FOR REMOVAL THROUGH MILLING OF SMALL AND MEDIUM SIZED WORK-PIECES WITH MEDIUM-LOW THICKNESS, SUITABLE FOR ROUND-TABLE MACHINES.

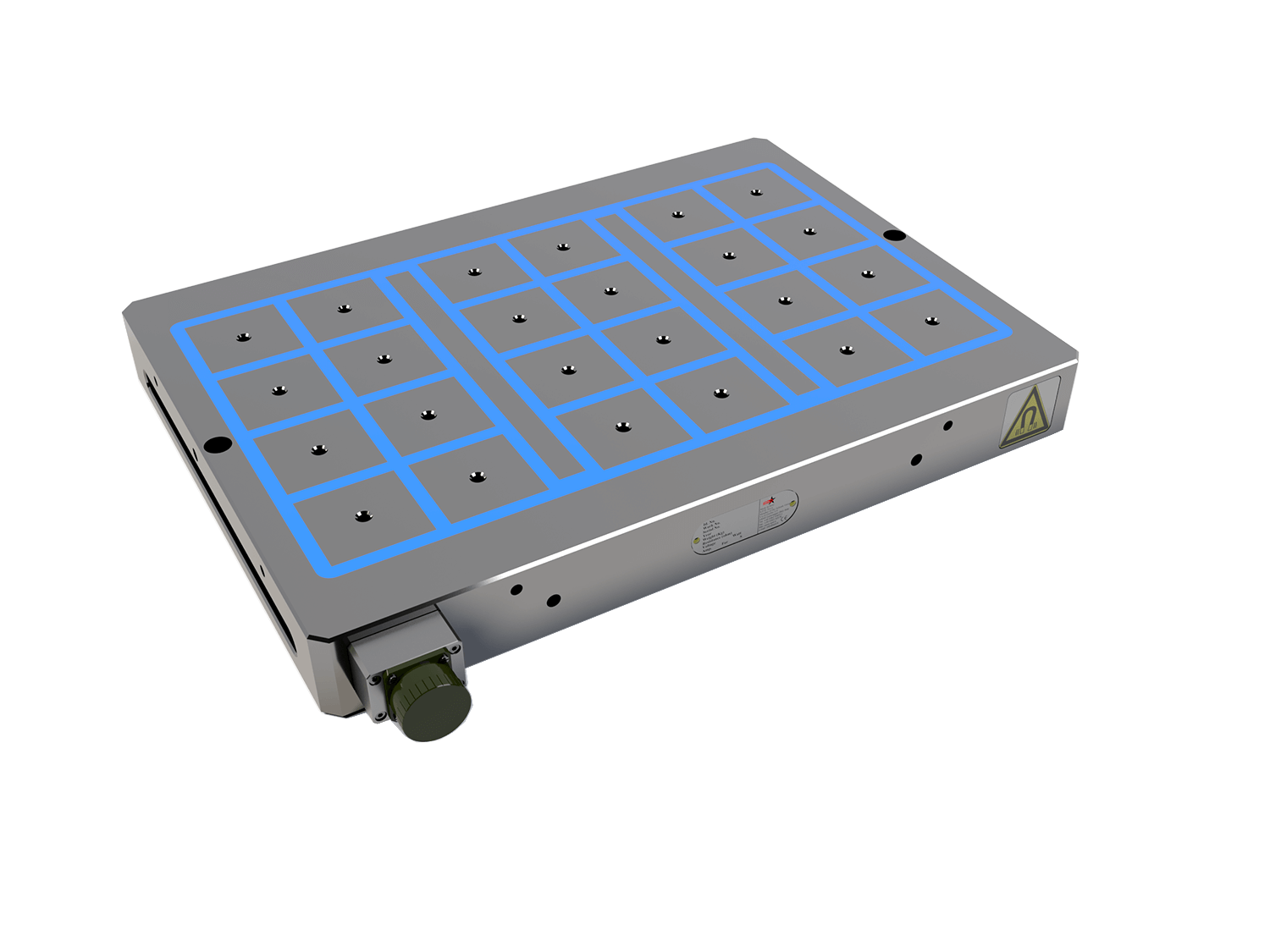

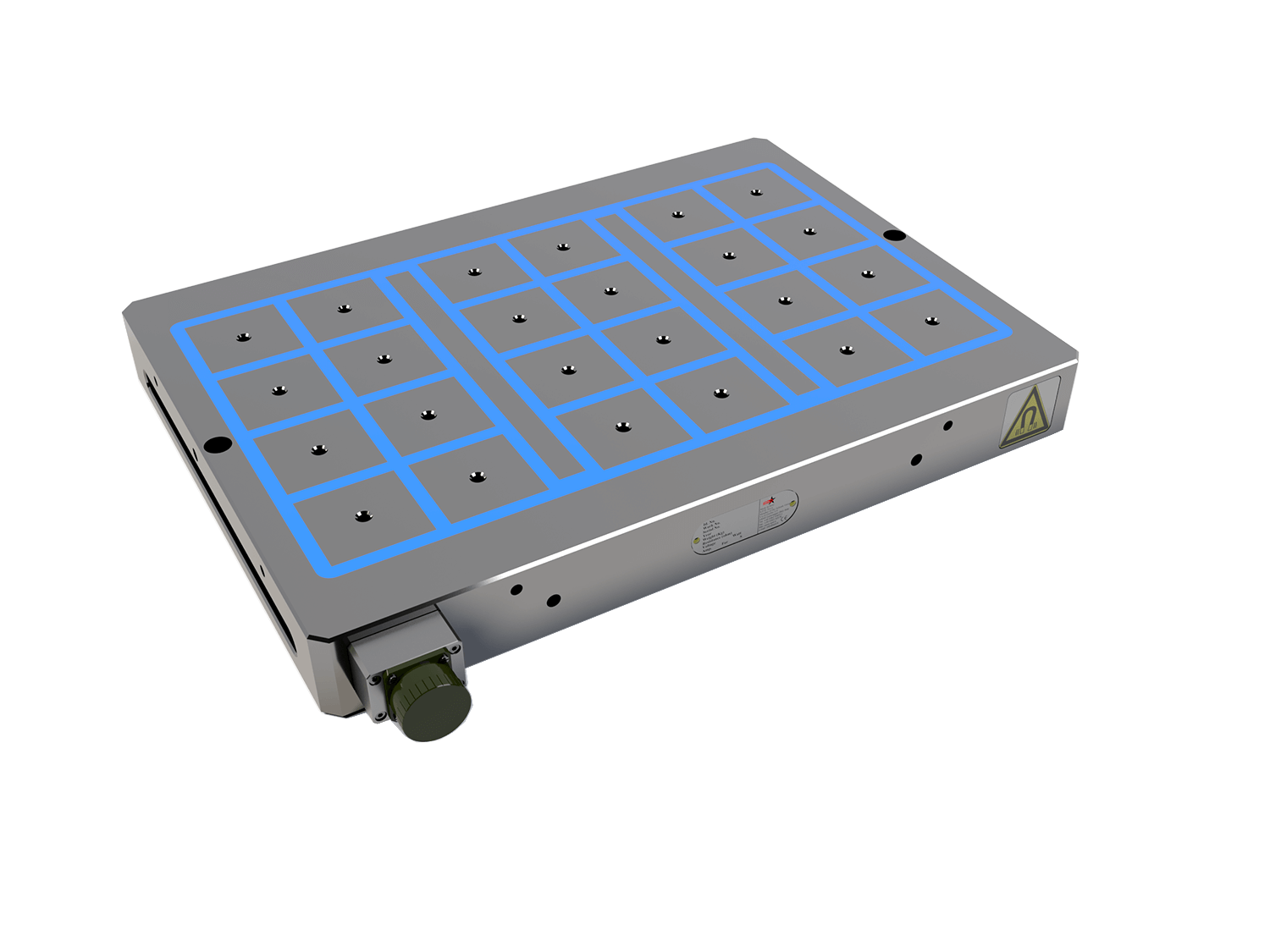

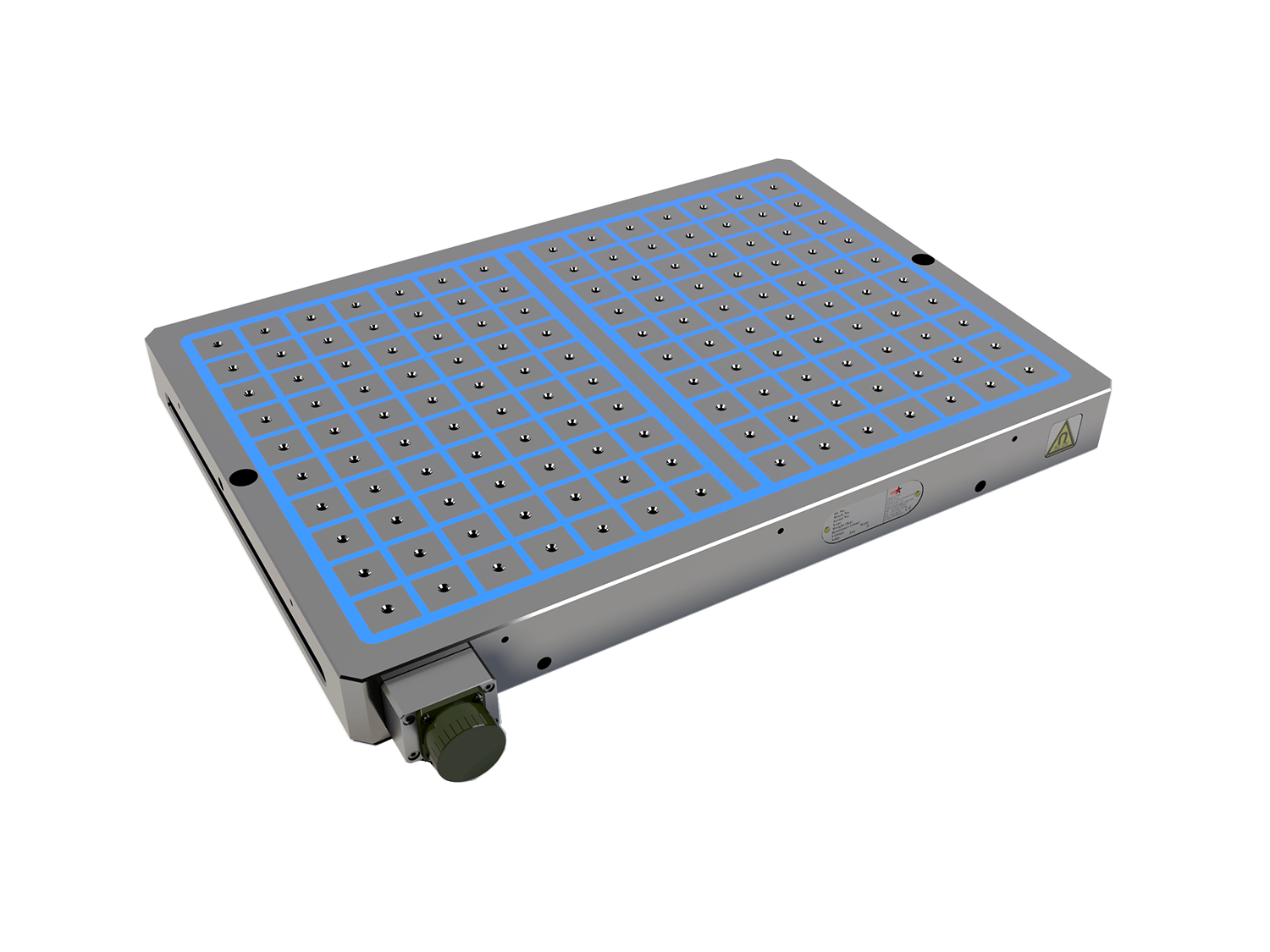

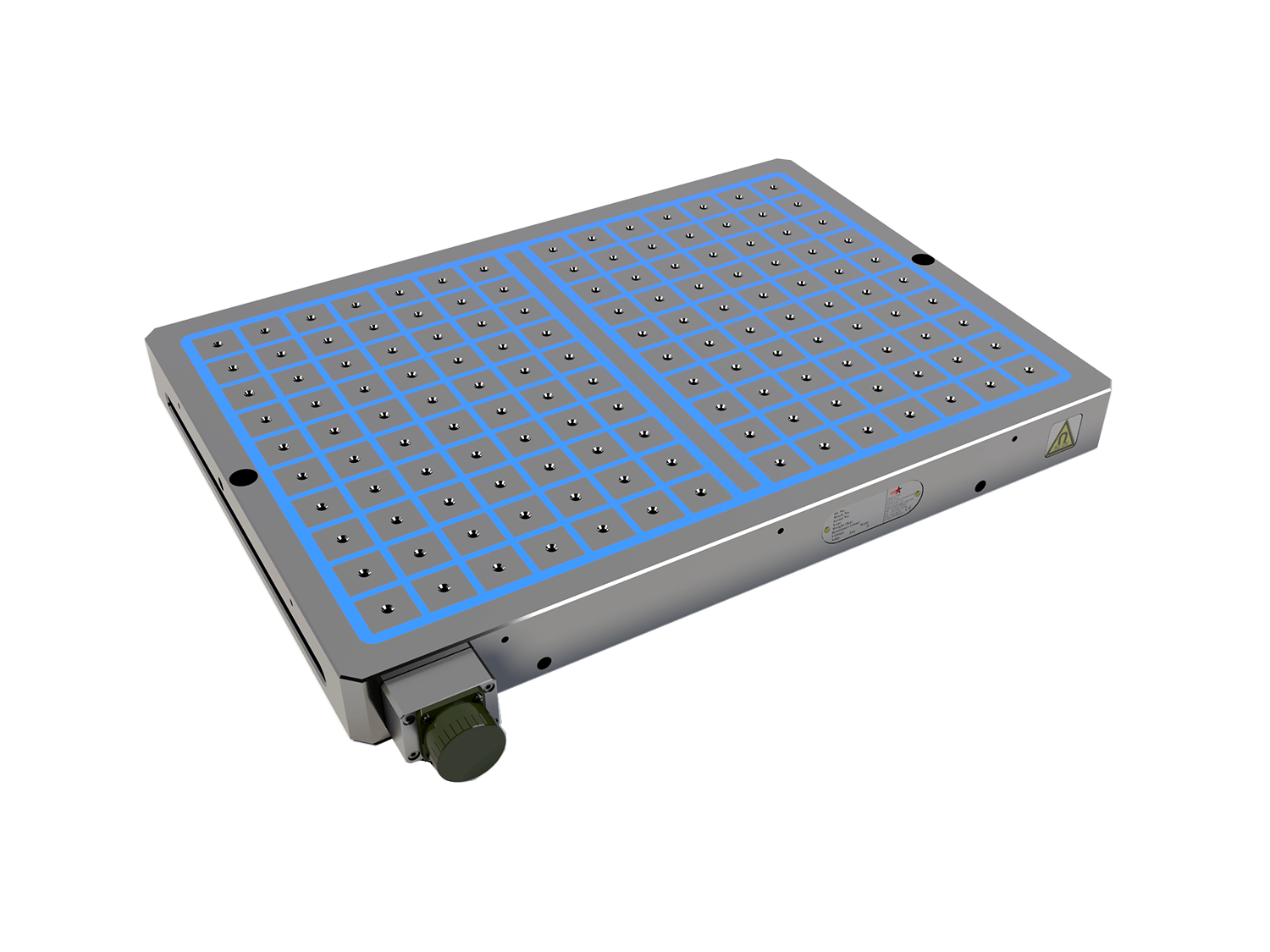

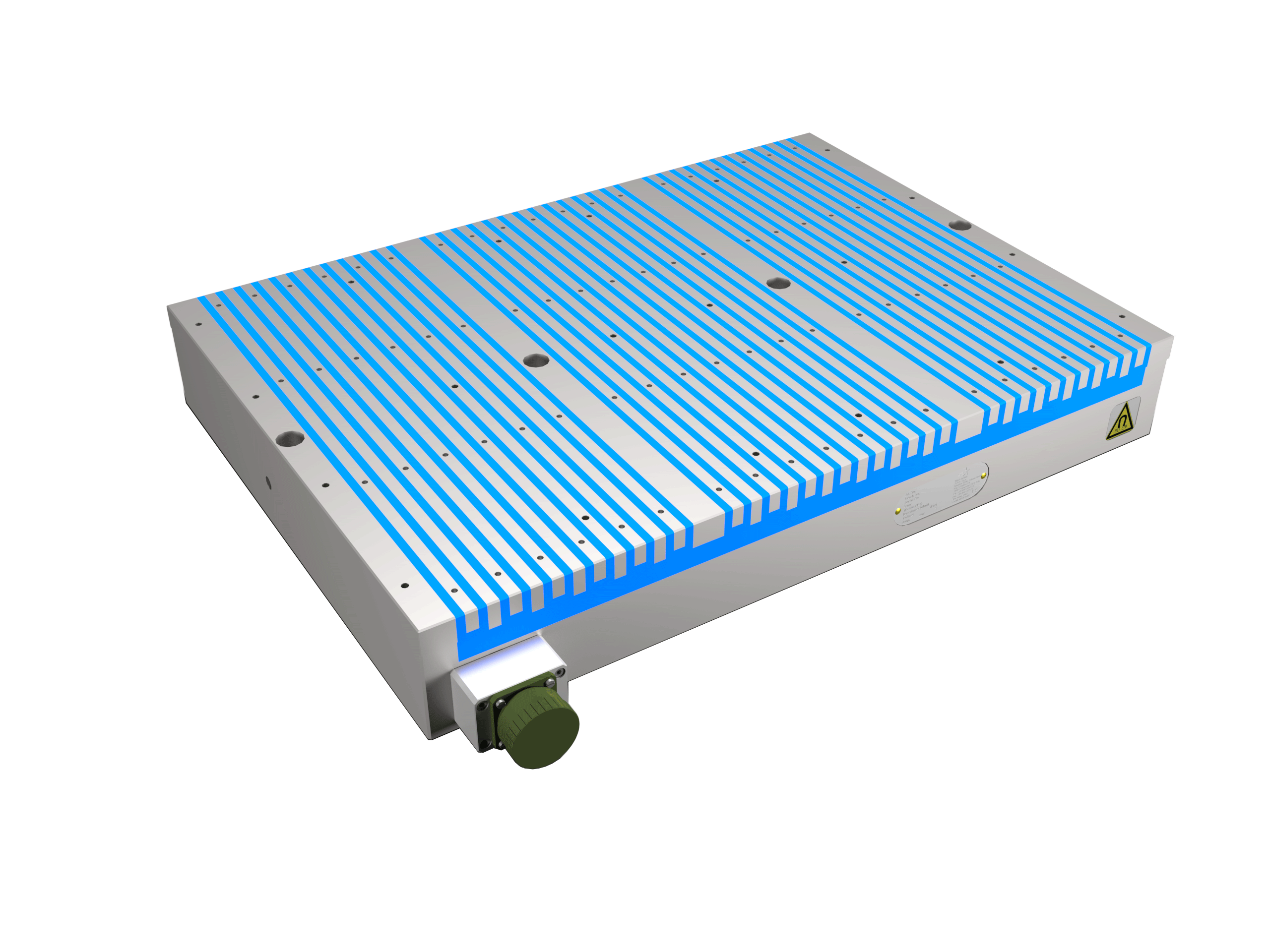

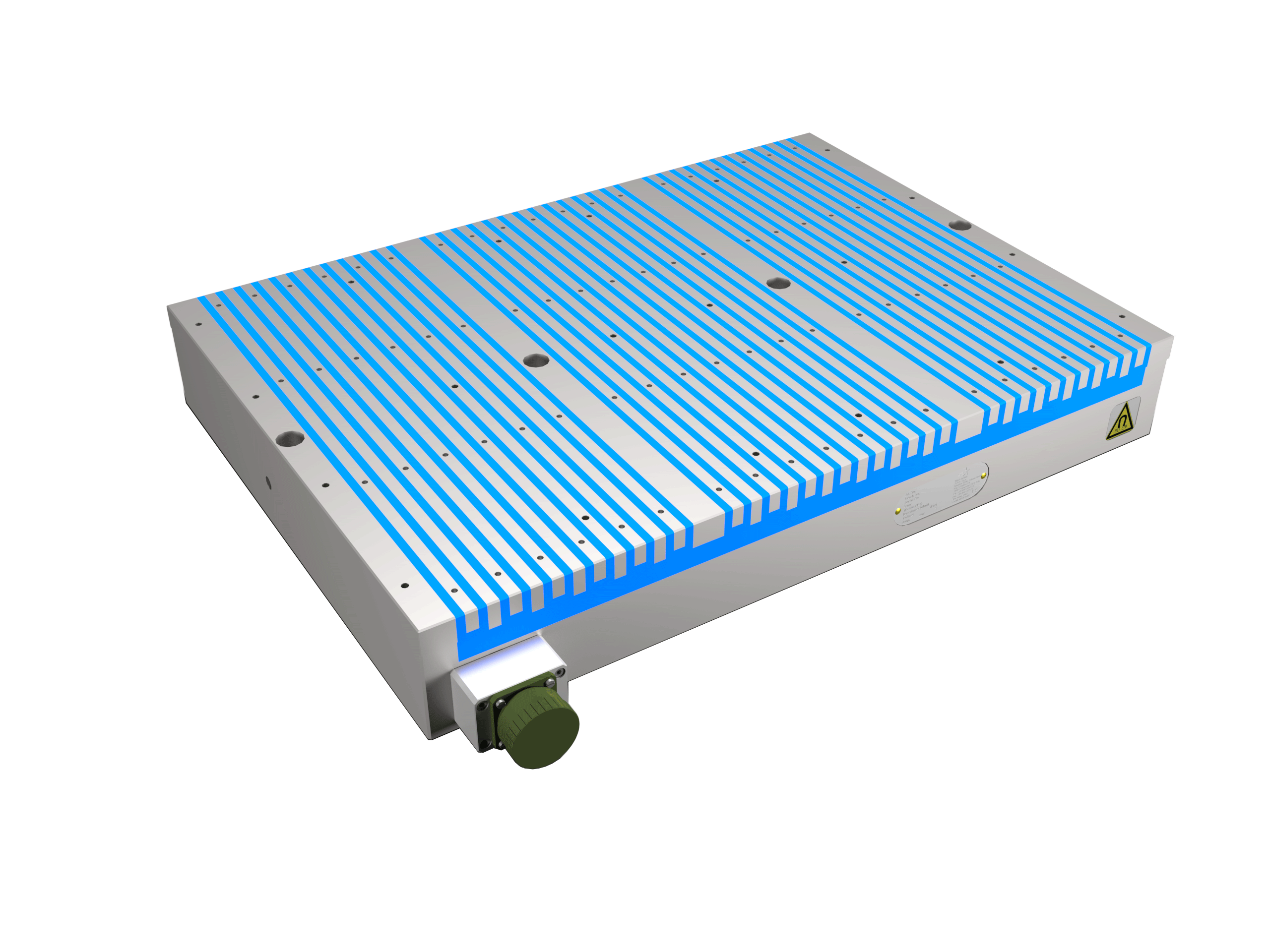

MFR-A2-050

ELECTRO-PERMANENT CHUCK FOR HIGH VOLUME MILLING USING POLE EXTENSIONS.

This is the most powerful model in the MFR series. It has a great magnetic force expressed specifically when work is carried out with pole extensions and unfinished work-pieces.

It is preferred to the A1 model in complex roughing applications on pole extensions of alloyed materials.

MFR-A1-070

ELECTRO-PERMANENT CHUCK FOR REMOVAL THROUGH MILLING OF PIECES WITH MEDIUM-HIGH THICKNESS.

It's the basic version of pole 70. Suitable for any type of work on medium and large size work-pieces, with unfinished or finished surface. Recommended for laminated materials. Ideal for composite solutions to cover large machine tables.

MFR-A2-070

ELECTRO-PERMANENT CHUCK FOR LARGE REMOVALS ON ANY TYPE OF MATERIAL WITH THE USE OF POLE EXTENSIONS.

It is the most powerful magnetic chuck on the market. A great magnetic force allows it to clamp pieces with high air gaps and to handle large removals. With the help of flexible and fixed extensions, it is ideal for processing highly deformed workpieces such as cast iron, forged parts, high-alloy mould steels. Recommended for processing squared work-pieces.

MFR-A1-032

ELECTRO-PERMANENT CHUCK FOR REMOVAL THROUGH MILLING OF THIN-WALLED WORK-PIECES.

Magnetic chuck specifically recommended for non-heavy milling operations on small or thin pieces. The high grip in the first millimetres of the work-piece is the strength of the unique product on our market. Recommended for high speed machining centres

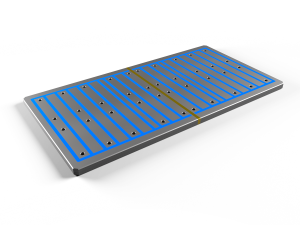

MFP-A1-L30

ELECTRO-PERMANENT CHUCK FOR REMOVAL THROUGH MILLING ON MEDIUM-LOW THICKNESS WORK-PIECES WITH IRREGULAR OUTLINE

This is the classic parallel pole chuck for milling applications, optimised for maximum versatility, specific strength and a wide choice of pole extensions (fixed, flexible, upper plates). It gives its best with medium-low thickness work-pieces, of complex and irregular outline, thanks to the ease in obtaining the correct balance of North and South polarity.

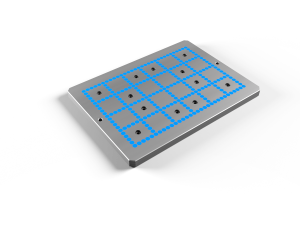

MFP-A1-L08

ELECTRO-PERMANENT CHUCK FOR REMOVAL THROUGH MILLING OF SMALL AND THIN-WALLED WORK-PIECES.

It is the only real solution on the market for milling small and thin parts, where other electro-permanent solutions show their limitations. The very fine pitch allows optimal flux control on low thicknesses, thus ensuring the best possible clamping force and the elimination of problems related to chip evacuation. The all-metal clamping surface provides stability, precision and durability; the top/upper plate is also replaceable, allowing easy repairs in case of accidental damage or special needs.

ACCESSORIES

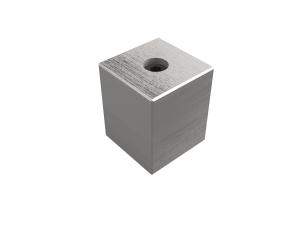

Fixed extensions

Fixed pole extensions, available in various sizes and equipped with screws, ensure a precise support of the work-piece on the surface of the magnetic module. This makes it perfect for machining smooth or machined work-pieces. They significantly improve the operating space for the machine, for example in the case of contouring and through-hole drilling operations. The extension is designed to ensure that the flux transmission from the chuck plate to the clamping surface, takes place with minimum loss, ensuring the safe clamping even of more complex work-pieces.

| Model | Code | Pole | Base | Height |

| PVR-32-10 | 0422998 | 32 | Ø30 | 10 |

| PVF-32-15 | 0422999 | 32 | 30x30 | 15 |

| PVF-32-23 | 0422404 | 32 | 30x30 | 23 |

| PVR-50-15 | 0420093 | 50 | Ø55 | 15 |

| PVF-50-20 | 0420090 | 50 | 45x45 | 20 |

| PVF-50-32 | 0422391 | 50 | 50x50 | 32 |

| PVF-50-54 | 0420091 | 50 | 45x45 | 54 |

| PVR-75-15 | 0422992 | 70 | Ø80 | 15 |

| PVF-75-30 | 0422993 | 70 | 70x70 | 30 |

| PVF-75-47 | 0422995 | 70 | 70x70 | 47 |

| PVF-75-70 | 0422997 | 70 | 70x70 | 70 |

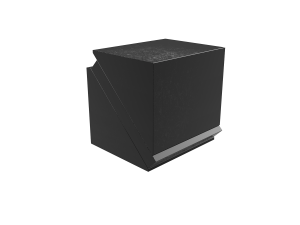

Flexible extensions

The flexible pole extensions, consisting of a lower part fixed to the poles and a sliding upper part, allow the height adjustment of the working surface of the chuck compensating for any deformation of the work-piece (automatic thickness adjustment). When, for example, a raw and deformed (bent) plate has to be levelled, the magnetic clamping force would tend to straighten it and consequently, once the work has been completed and the slab plate demagnetised, there would be an elastic return effect, that would not allow the elimination of the deformation. By means of flexible extensions it is possible to adapt to the deformation of the plate, to clamp it during the first levelling phase and, once rotated for the second machining, to obtain an excellent flat surface. It is important for the plate to always rest on at least three suitably established fixed points, which will act as a constant reference point for the work surface.

| Model | Code | Pole | Base | Nominal Height | Height Min | Height max |

| PVB-32-23 | 0422405 | 32 | 29x31,5 | 23 | 18 | 25 |

| PVB-50-32 | 0422392 | 50 | 47x45 | 32 | 27 | 34 |

| PVB-50-54 | 0420092 | 50 | 47,2x45 | 54 | 49 | 56 |

| PVB-75-47 | 0422994 | 70 | 70x70 | 47 | 42 | 49 |

| PVB-75-70 | 0422996 | 70 | 70x70 | 70 | 65 | 72 |

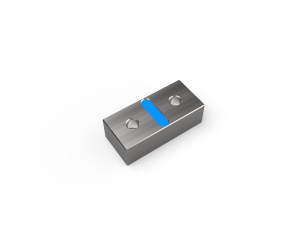

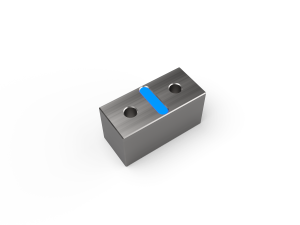

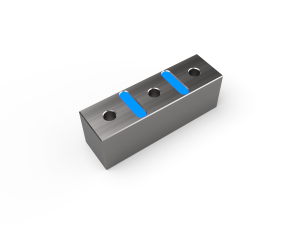

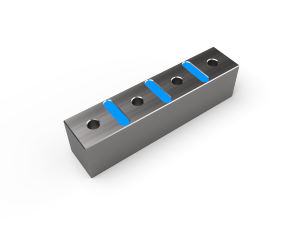

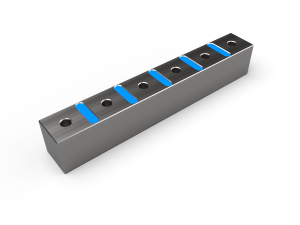

Pole bars

The pole bars are fixed multi-pole extensions allowing the rapid creation of support and reference mounts, side stops and the use of centring pins. They are widely profilable and quickly replaceable, available in modular formats to be assembled according to the clamping requirements.

| Model | Pole | Parts | Base | Height | Weight (kg) |

| PVP-50-30-2 | 50 | 2 | 110x50 | 34 | 1,5 |

| PVP-50-30-4 | 50 | 4 | 110x110 | 34 | 3,2 |

| PVP-50-30-6 | 50 | 6 | 170x110 | 34 | 5 |

| PVP-50-30-8 | 50 | 8 | 230x110 | 34 | 6,8 |

| PVP-50-30-12 | 50 | 12 | 350x110 | 34 | 10,3 |

| PVP-50-30-16 | 50 | 16 | 230Xx230 | 34 | 33 |

| PVP-50-57-2 | 50 | 2 | 110x50 | 57 | 2,5 |

| PVP-50-57-3 | 50 | 3 | 170x50 | 57 | 3,8 |

| PVP-50-57-4 | 50 | 4 | 230x50 | 57 | 5,2 |

| PVP-50-57-6 | 50 | 6 | 350x50 | 57 | 8 |

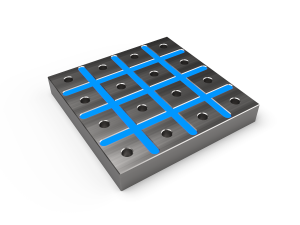

Pole plates

When the clamping surface requires contouring, or when the chuck needs a chip wear protection or a pole pitch change (parallel pole magnets), the square or parallel pole plates are able to provide an additional support. These plates are accessories available in different sizes and formats for a better adaptability to standard magnetic chucks, but can also be produced in special sizes.