IMPORTANCE OF THE POLE PITCH

The real reason for choosing a magnetic chuck over another is the ideal pole pitch for the work-piece

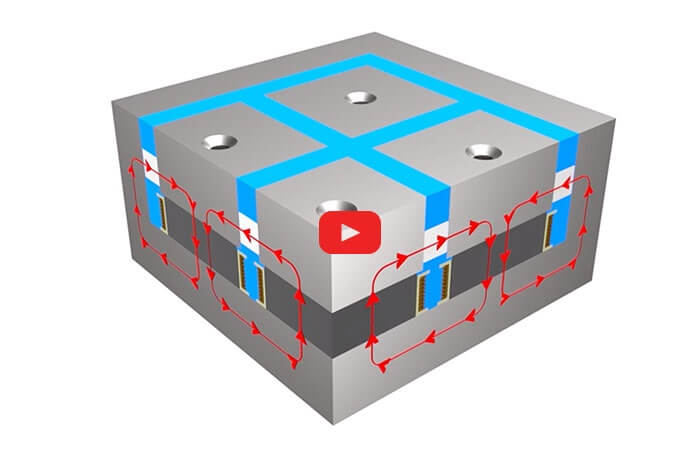

DOUBLE MAGNETIC FLUX

Static permanent magnets are located along the sides of the poles, while invertible magnets are located underneath the same.

The coils around the invertible magnets quickly generate an electromagnetic field that reverses their polarity in fractions of a second. The resulting total flux of the chuck can be directed outwards towards the work-piece to be clamped (magnetising phase) or short-circuited inside the chuck (demagnetising phase), thus eliminating any magnetic residue from the contact surface to release the work-piece.

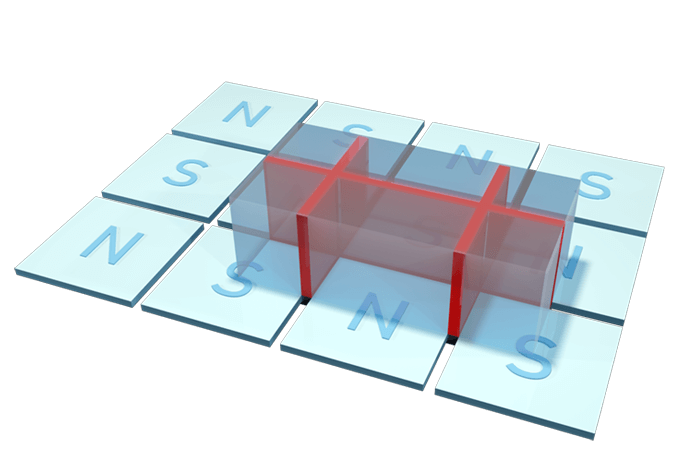

CHESSBOARD ARRANGEMENT

The poles are laid out in a chessboard pattern, and are obtained by alternating North and south polarities. The magnets arranged this way generate the clamping force when activated.

Activation occurs using an electronic control device, and its duration is less than one second. The magnetic module will then remain active, without any further energy supply for as long as necessary.

MAGNETIC CIRCUIT

The magnetic chucks are available in two different versions to offer the widest possible coverage for any clamping requirements.

The A1 version with high magnetic field density is suitable for all types of work on laminated parts.

The A2 version offers a higher magnetic field density allowing large removals even on work-pieces with uneven surfaces (e.g. forged, steel or cast iron pieces).

Applying pole extensions to this type of chucks, guarantees a reduced power loss.

NEUTRAL RIM

The external frame of the chuck, besides containing the components, has also the function of conveying the magnetic fluxes and isolating the active surface of the chuck from the machine.

The result is a total magnetic insulation that avoids the phenomena of chips sticking to the tool due to dispersed fluxes.

POLARITY

POLE 50

Characterised by its extraordinary clamping versatility that makes it suitable for processing small or thin work-pieces (with a minimum thickness of 8 mm), with both unfinished and finished surfaces.POLE 70

It is suitable for all kinds of machining on medium and large size work-pieces with thickness greater than 20 mm.POLE 32

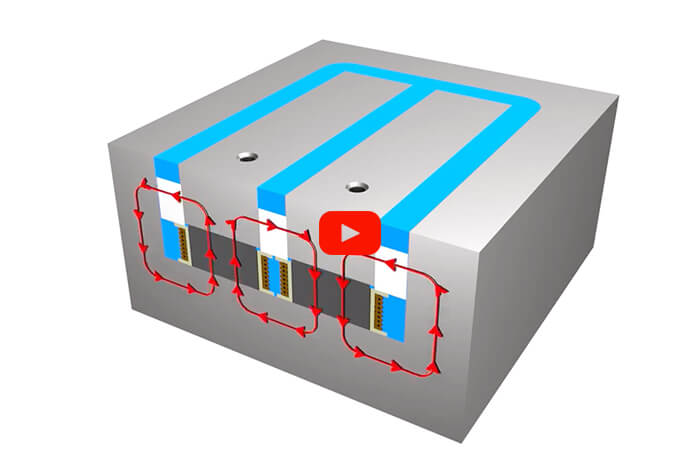

Suitable for small and very thin work-pieces on high-speed machining centres.DOUBLE MAGNETIC FLUX

Static permanent magnets are located along the sides of the poles, while invertible magnets are located underneath the same.

The coils around the invertible magnets quickly generate an electromagnetic field that reverses their polarity in fractions of a second. The resulting total flux of the chuck can be directed outwards towards the work-piece to be clamped (magnetising phase) or short-circuited inside the chuck (demagnetising phase), thus eliminating any magnetic residue from the contact surface to release the work-piece.

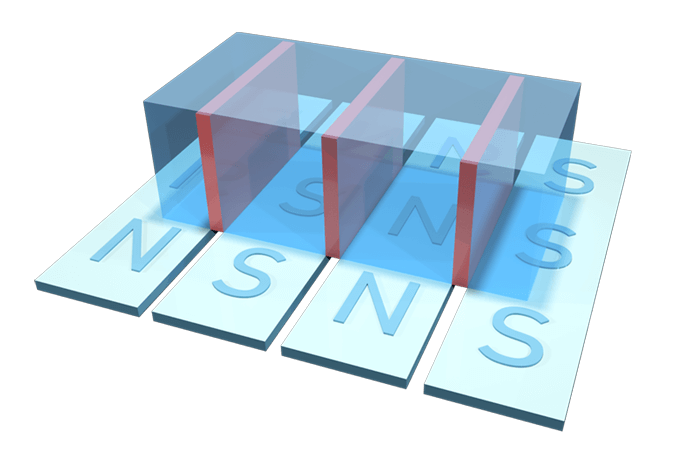

PARALLEL POLES ARRANGEMENT

The longitudinal poles are laid out parallelly, alternating between north and south polarities. The magnets arranged this way generate the clamping force when activated.

Activation occurs using an electronic control device, and its duration is less than one second. The magnetic module will then remain active, without any further energy supply for as long as necessary.

NEUTRAL RIM

The external frame of the chuck, besides containing the components, has also the function of conveying the magnetic fluxes and isolating the active surface of the chuck from the machine.

The result is a total magnetic insulation that avoids the phenomena of chips sticking to the tool due to dispersed fluxes.